This video and blog post was extracted from a Reconstruct webinar on digital twins and 3D reality mapping on August 25, 2021.

David Cheyne, Senior Associate at WJE and Mani Golparvar, CTO and Co-Founder at Reconstruct, illustrate how owners and engineering firms can use visual data -- collected with drones and 360-degree cameras -- together with cloud-based inspection systems to enable enhanced, cost-effective inspections.

Key Takeaways

Digital Twin technology can now be reliably used to perform accurate inspections. A digital twin is a virtual representation that serves as the real-time digital counterpart of a physical object or process.

- Digital twins reduce time spent traveling to inspections, performing inspections, entering data and reviewing the inspection.

- Digital twins empower inspection stakeholders to spend less time manipulating data and preparing reports.

- Digital twins reduce time to manage inspections and communicate recommendations.

The Challenge of Inspections

The $20 trillion US economy relies on a vast network of physical structures -- from roads to bridges to commercial and residential buildings. However, many of these assets are structurally deficient, making inspections and maintenance imperative. But inspection of physical assets is challenging for several reasons: 1) it is expensive and disruptive; 2) it can be dangerous to the inspection crews; 3) onsite documentation is time-consuming; and 4) assessments can be inconsistent.

The Value of Digital Twins for Inspections

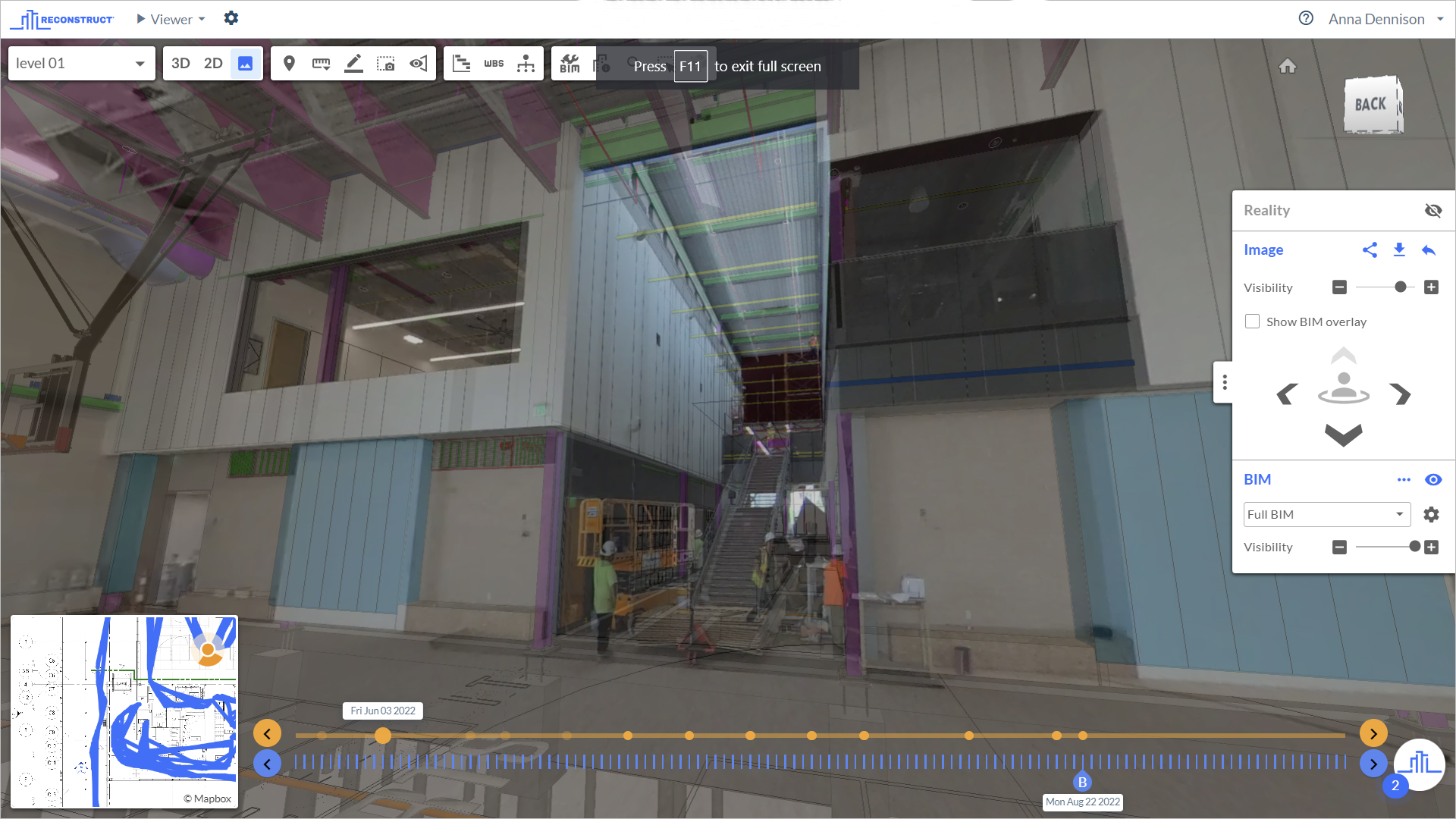

The use of digital twins and reality mapping for inspection of physical assets is a breakthrough. Through AI-generated digital twins, models and floor plans are accessible anytime, anywhere. Inspection teams are able to utilize any type of reality capture (phone camera, 360 camera, drone, laser scanner, etc) to capture the site. The result is a measurable, street-view experience that can be easily navigated and inspected.

WJE talks about the benefits of using digital twins for inspection such as:

- Pre-assessments can be performed in the office

- Inspection on-site can be reduced

- Measurements can be done prior to on-site assessment

- Project teams and equipment can be “right-sized” prior to going on site

- Specialists from across the organization can lend their expertise to any project

- Assessment teams can return virtually after completion of the visit

Due to covid, WJE specialists have been limited in travel for the past year and a half. Digital twins give their specialists the ability to perform assessments within the office or within the comfort of their own home. A lot of things can be picked up from the virtual walkthrough, minimizing and sometimes eliminating the need to go on site. There are also situations where they have very limited time to do the inspection due to covid-related restrictions. The WJE team is able to move in with a 360 camera, do the reality capture, then get out as quickly as possible without compromising quality.

Documenting Visual and Non-Visual Data

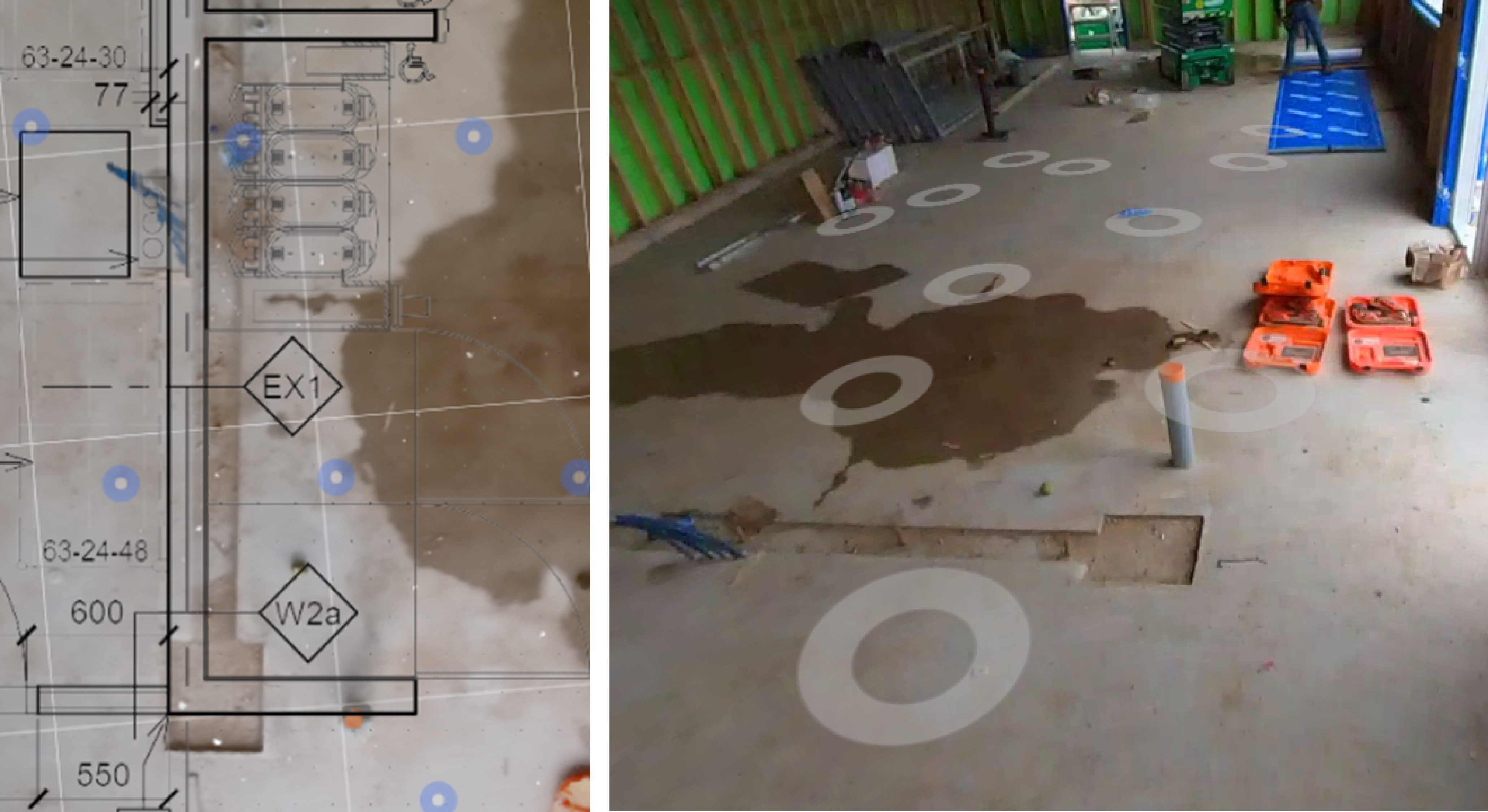

With digital twins, inspection stakeholders are able to tag various forms of information to associate it with the visual data. The approach is both visual and virtual. There is one single repository that shows the physical asset, and assessments are preserved over time. Inspection teams can go back and compare and contrast the state of any defect over time.

There are 4 key capabilities an inspection team gains by using digital twins:

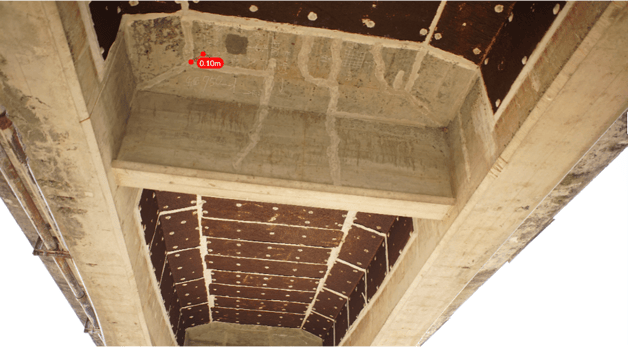

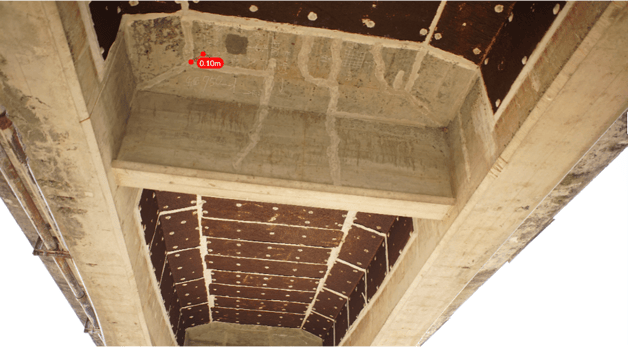

- Visual inspection can be done in images. An inspector can find images based on current view or 3D and do a deep zoom to see fine details.

- Measurements such as length, angle, area and coordinates can be done within the images. An inspector can also use 3D to measure directly on images.

- Documentation and mark ups of the images. An inspector can pin defects, location, type, severity, add notes, and even communicate this information in real-time via email and text.

- Changes over time are tracked. Inspectors can see models and images at various points

Digital Twin of a Bridge: An inspector can find images based on current view or 3D and do a deep zoom to see fine details.

Measuring Using Digital Twins: Measurements such as length, angle, area and coordinates can be done within the images.

Final Note: The use of digital twins is not limited to inspection. Other use cases of digital twins include:

- Assessment of physical assets

- Extreme events response and recovery

- Insurance claims

- Compliance checks such as ADA compliance

About Reconstruct

Reconstruct’s patented technology enables more thorough and efficient building inspections while delivering a digital twin of each structure for future operation and maintenance. For more information on Reconstruct, contact us here.

About WJE

Wiss, Janney, Elstner Associates (WJE) is a global firm of engineers, architects, and materials scientists specializing in inspections and helping clients solve, repair, and avoid problems in the built world.