Key Challenges

Texas A&M’s construction team acts as an owner’s representative for the Texas A&M Board of Regents - the entity that approves and owns the university’s capital projects. With hundreds of simultaneous projects under management, the team is always looking for a better way to capture percent complete and project quality while keeping all stakeholders aligned.

The Solution

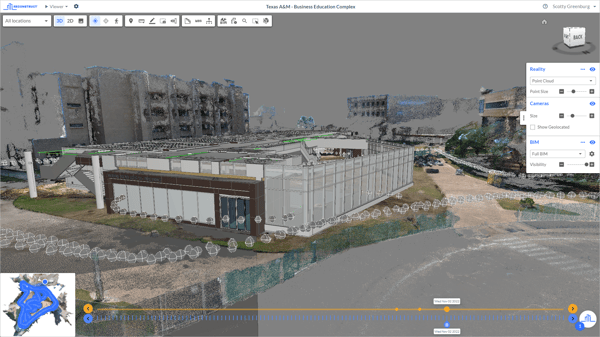

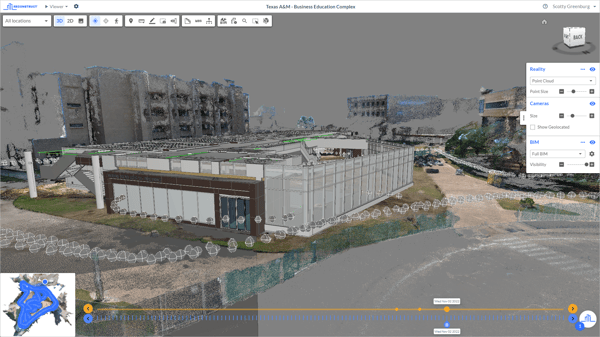

Reconstruct empowers Texas A&M teams in managing time-stamped documentation, quality control, and stakeholder visibility on multiple projects, most recently a 4-story, 83,000-square-foot facility slated for completion in November 2024.

Reconstruct empowers Texas A&M teams in managing time-stamped documentation, quality control, and stakeholder visibility on multiple projects, most recently a 4-story, 83,000-square-foot facility slated for completion in November 2024.

By utilizing reality capture from an existing drone, 360° camera, or laser scan, Reconstruct produces a realistic, measurable model of the as-built conditions of any site that can be overlaid with design drawings and BIM models for seamless comparison of planned design to the as-built. What does this mean for Texas A&M:

- In under an hour a week, a project team member can walk the site with a 360° camera, capture and upload footage into Reconstruct, and deliver unprecedented access to a realistic site walk experience for all stakeholders.

- Inside of Reconstruct, they can compare any available designs to reality at every stage of the project.

- During construction, handoff, and operation, Texas A&M has complete as-built documentation for every building using Reconstruct—knowing where and when everything was installed on what date.

Value Delivered Today and for Years to Come

Chase Miller, Project Manager at Texas A&M, takes every opportunity to share the value of Reconstruct with fellow team members and project owners.

2. Knowing what's there vs. what should be there

"I recommend Reconstruct for my projects, but especially for builds that have their designs specified. Reconstruct works uniquely to show what was installed versus what is supposed to be there in sub-inch alignment for us. And it stays updated as the designs are updated. Reconstruct is a very good coordination tool, basically documenting the project as it's being built versus waiting for a subcontractor to give me a paper as-built.”

3. Conflict and claim resolution during and after the project

“If I had a claim or we had a conflict, from a project management standpoint, it's a tool that I could go back and say [to a contractor], ‘The model shows this going here, however you installed it five feet off… and then say that because of their install, something screwed up, I can go back and basically show exactly where it's supposed to be, why it's supposed to be there’. I think that's the biggest thing for us: everything that's designed and put in the model is put in there for a reason.”

4. Instant as-built visibility for facility management

“It's invaluable to the facilities team because it's live as-built. Without ripping a wall down, you can tell exactly what's in it, know exactly where penetrations are, and know exactly what's in a ceiling without taking ceiling tiles down.”

Reconstruct empowers Texas A&M teams in managing time-stamped documentation, quality control, and stakeholder visibility on multiple projects, most recently a 4-story, 83,000-square-foot facility slated for completion in November 2024.

Reconstruct empowers Texas A&M teams in managing time-stamped documentation, quality control, and stakeholder visibility on multiple projects, most recently a 4-story, 83,000-square-foot facility slated for completion in November 2024.