At Reconstruct, we believe that technology—in particular, artificial intelligence—will reshape how stakeholders in construction, inspection, and engineering plan, visualize, and monitor their projects. In this article, we’ll discuss in detail how Meta’s recognition tool, Segment Anything Model (SAM), may play a significant role in these industries’ evolutions.

Key takeaways:

- Segment Anything Model (SAM) is an AI tool that enables easy segmentation of objects (such as masks, pipes, and windows) from an image.

- Since SAM can hasten annotating and training processes of recognition technology, SAM could play a significant role in construction progress monitoring, QA/QC, and more.

What is SAM (Segment Anything Model)?

SAM is an AI tool that allows users to segment objects from an image quickly. For example, in the picture provided below, the user needs only hover their cursor over the desired object to segment it. The user can easily segment out a whole object, such as a worker, or one part, such as the worker’s mask.

When we refer to segmentation, we mean the process by which human or artificial intelligence determines which pixels correspond to a desired object.

Why is SAM such a big deal for the construction industry?

Typically, creating new recognition models requires tedious and expensive annotations. For example, suppose you wanted your recognition software to identify face masks. To train the recognition model, you’d need to find a bunch of images of face masks and segment them out.

Then, you might want to detect hard hats, boots, gloves, tools, and various other equipment. All told, companies often spend millions of dollars annotating image data so they can train their systems to recognize objects of interest.

With SAM, this annotation and training process can be 50 to 100 times faster, not only because it’s so much faster to segment the objects, but also because it’s easier to search image collections for similar objects. This makes it much faster to find and annotate objects of interest. Many data annotation services are already leveraging SAM, and the lower cost to collect data will lead to widespread recognition capabilities.

As a result, this technology could play a significant role in construction progress monitoring. For example, stakeholders may ask the technology whether work on pipes has been completed or how many windows have been installed on a given project.

For visual quality assurance and quality control, recognition can help determine whether things are installed in the right place and whether there are any defects. For safety monitoring, recognition can be asked to determine whether field teams are wearing the proper personal protective equipment. While it’s true that recognition technology has achieved some of these tasks in the past, SAM will lead to improved accuracy and customization of recognition models.

What’s more, SAM may help propel AI forward with improved “reasoning.” Current state-of-the-art Transformer models process an image by comparing and aggregating information based on patches of pixels. By breaking down an image into objects and parts, SAM makes it possible to interpret scenes as collections of objects and their interactions.

By bringing representations up to the object level, it becomes easier to analyze multiple images together with other project data to perform tasks like asset tagging, measuring productivity, and determining the activities of field teams.

Related: Remote Construction Monitoring: The Key to Building Sweden's Tallest Office Tower

About Reconstruct

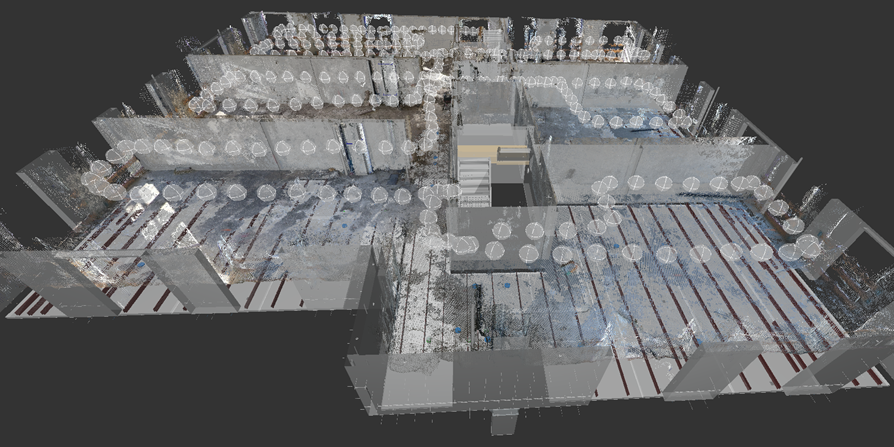

Reconstruct has set the gold standard for digital twinning across the construction, inspection, and engineering industries. Our reality mapping technology allows stakeholders to blend all geo-referenced reality capture footage together to create one automatically generated, as-built digital twin for construction, creating a true archive of work in space and over time.

What’s more, Reconstruct allows virtually any employee to perform quick, data-rich reality capture in a matter of minutes. As a result, it’s easier than ever for organizations with even modest budgets to perform remote visual progress monitoring, current facility condition assessments, and site surveys in both 2D and 3D.

To see your project and Reconstruct or to learn more about how technology is reshaping the industry, https://reconstructinc.com/request-demo feel free to contact us.

.png)