Whether you work in construction, inspection, or engineering, chances are you require a physical inspection of a building, structure, or infrastructure at some point in time. While such physical asset inspections and site surveys often occur before construction, they are also frequently performed during construction to enable remote project monitoring and once construction is completed for final documentation of finished work. Moreover, additional inspections are performed regularly after construction is complete in the inspection and engineering industries.

In this article, we’ll define physical, in-person asset inspections and visual, remote asset inspections. We’ll also discuss the drawbacks and benefits of each asset inspection, zeroing in on the many similarities. Finally, we’ll dive into the nuances of asset inspection and demonstrate how blending physical and visual asset inspections often provides stakeholders with the data and insights they require at a fraction of the cost.

Key takeaways:

- A physical asset inspection refers to an on-site, comprehensive, and hands-on examination of a structure or infrastructure. It is often performed by an expert and may be expensive and require travel.

- A visual asset inspection is performed remotely by an expert who views a virtual duplication of a job site, structure, or infrastructure. These assessments are inherently less expensive, faster, and often safer than physical inspections.

- Increasingly more construction, engineering, and inspection stakeholders rely on remote, visual asset inspections for routine monitoring of structures, reserving physical inspections for only when necessary. This allows for significant budget reallocation away from unnecessary hands-on inspection.

What is a physical assets inspection?

A physical asset inspection includes an on-site, comprehensive examination of a building, structure, or infrastructure. Usually, such an inspection involves dispatching inspectors or engineers directly to the asset site. Once there, these experts can assess the asset's condition, integrity, and vulnerability.

While on-site, these experts will typically take copious pictures and notes, allowing them to provide an in-depth assessment. Inspectors also conduct examinations, perform critical tests, and collect samples if necessary. The experts then evaluate a structure's condition and identify all concerns.

Physical asset inspections are particularly beneficial for detecting complex or disguised issues. This means that the on-site expert may notice problems that are difficult to ascertain or nearly impossible to capture using a recording device.

On the other hand, physical asset inspections can be prohibitively expensive. This is especially true for niche industries, where there may be limited numbers of experts worldwide who can perform such inspections. Simply flying out the expert and paying for their time could cost a small fortune. This is precisely why more and more companies are choosing to utilize physical asset inspections only when necessary.

What is a visual asset inspection?

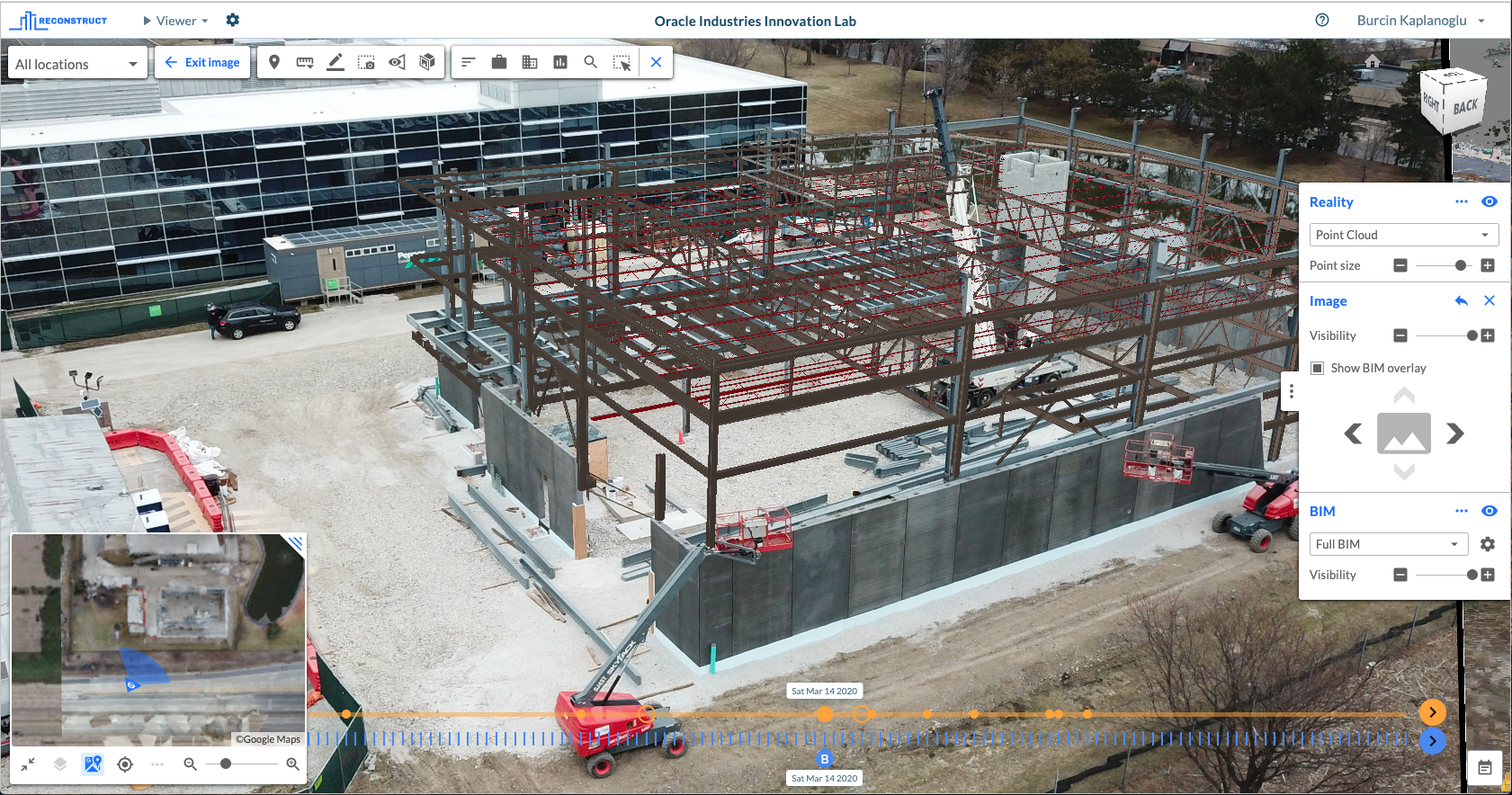

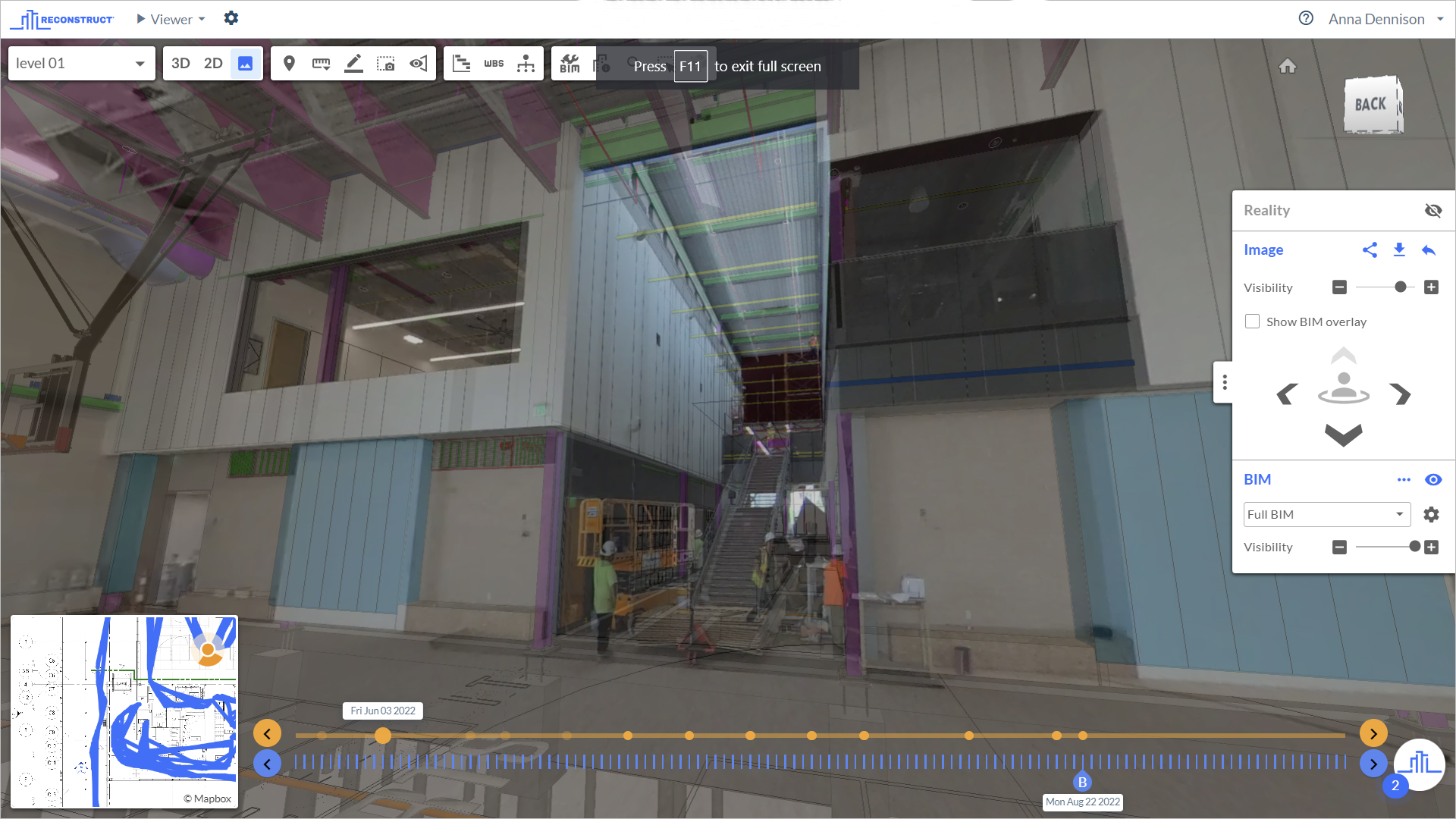

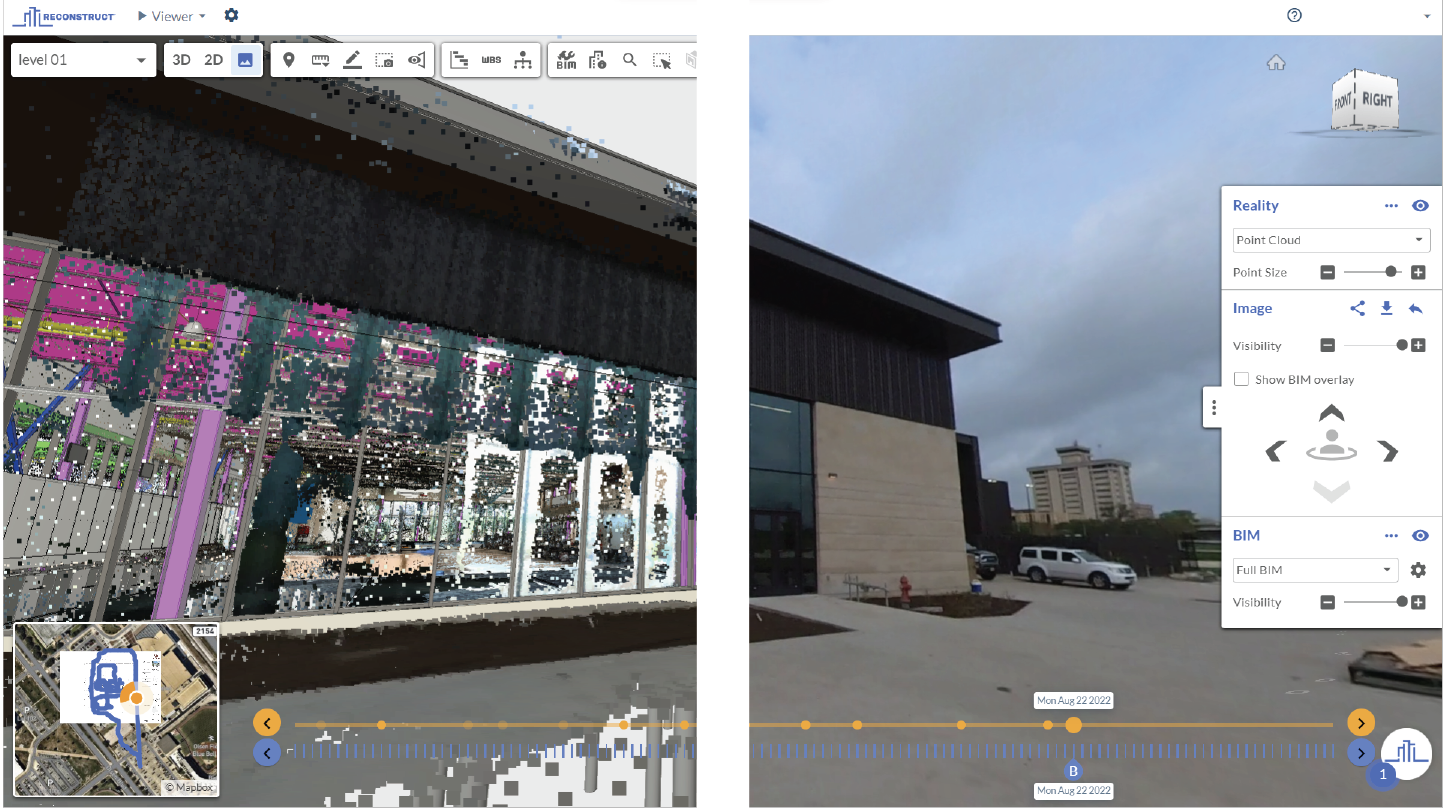

A visual or remote asset inspection leans on technology and remote visualization to assess an asset's condition from afar. In other words, during a remote asset inspection, the reality of the structure or infrastructure is captured using hardware, then sent to a photogrammetry engine to produce both 2D and 3D reality models of whatever has been visualized.

Then, an expert is asked to review the inspection without the cost of extensive travel and time spent on site. In lighter use cases where an expert-level inspector is not required, visual asset inspection allows even multi-site portfolio managers to review the condition and status of dozens of stores while traveling to none.

In other words, one of the chief benefits of visual asset inspection is remote viewing. Whether the remote viewing is performed later or in real-time, visual inspections leverage technology such as smartphones, 360 cameras, and drones to produce unbelievably accurate digital twins. As photogrammetry engines grow smarter and more intelligent, these models become increasingly immersive, measurable, and precise.

Another benefit of visual asset inspection is improved accessibility and safety. The truth is that sometimes, physical asset inspections require a human to crouch into nooks and crannies that are simply unsafe. Fortunately, with the right software and hardware, devices such as drones can capture high-resolution duplications of structural elements in a hazardous environment.

An additional benefit of remote asset inspection is efficiency. For example, in the case of a gas station, the reality of the structure can be captured in 15 minutes or less. Then, visual data is fed to a photogrammetry engine and rapidly transformed into a digital twin. From here, the data can be leveraged for hundreds of purposes, including planning renovations and design, searching for wear and tear indicators, and ensuring structures are up to code.

Remote asset inspection can also assist in determining when a physical asset inspection is vital.

Related: 3 Construction Pain Points for Retail & Multi-Site Project Managers

What's better: physical assets inspection or visual asset inspection?

The choice between a physical asset inspection and a visual asset inspection isn't always cut and dry. Almost always, a combination of the two is best. In other words, it's usually wise to lean on visual inspection for routine monitoring while utilizing physical inspection for periodic, critical assessments.

For example, consider concrete structures. Anything made out of concrete demands regular inspection and may even be subject to state regulations that frequently require such inspections. That means stakeholders may need to regularly assess everything from cooling towers and power plants to parking garages and multi-story structures.

Visual asset inspection allows stakeholders to remotely assess the condition of the majority of structures. These facilities are known to be in good shape and are very low on an inspector or engineer's list of concerning sites. By utilizing reality mapping technology for these sites, stakeholders free up the resources required to inspect the remaining structures which require hands-on physical attention.

This is especially true when different structures were built under different building codes at different times. Inherently, some structures will always be higher risk and carry higher stakes than others. Remote asset inspection provides construction, inspection, and engineering stakeholders the flexibility to allocate resources toward in-person inspection when it matters, but otherwise default to visual asset inspection for routine facility assessment.

Another example? Look toward the multi-site and retail industry. Previously, some companies in this industry would employ regional engineers who drove or flew from site to site to perform asset inspection. Now, with the help of visual asset inspection, corporate can simply ask an on-site manager (or anyone, really) to perform a rapid reality capture of the structure using a device as simple as a smartphone or 360 camera.

In minutes, this footage can be transformed into a digital twin that can be reviewed alongside duplications and site surveys captured at every other store. In a single afternoon, remote engineers can stay put, see more in less time, and reduce costly, time-consuming travel. If and when necessary, these experts can always travel to the job site and inspect the store or restaurant more closely.

But almost always, a remote, visual inspection of the assets is enough.

About Reconstruct

Reconstruct empowers stakeholders across construction, engineering, and inspection industries to perform visual asset inspections usually virtually any device. Using a powerful photogrammetry engine, Reconstruct transforms geo-referenced reality capture data into a digital twin at any point along the asset’s life cycle.