What challenges do digital twins solve in construction, inspection, and engineering?

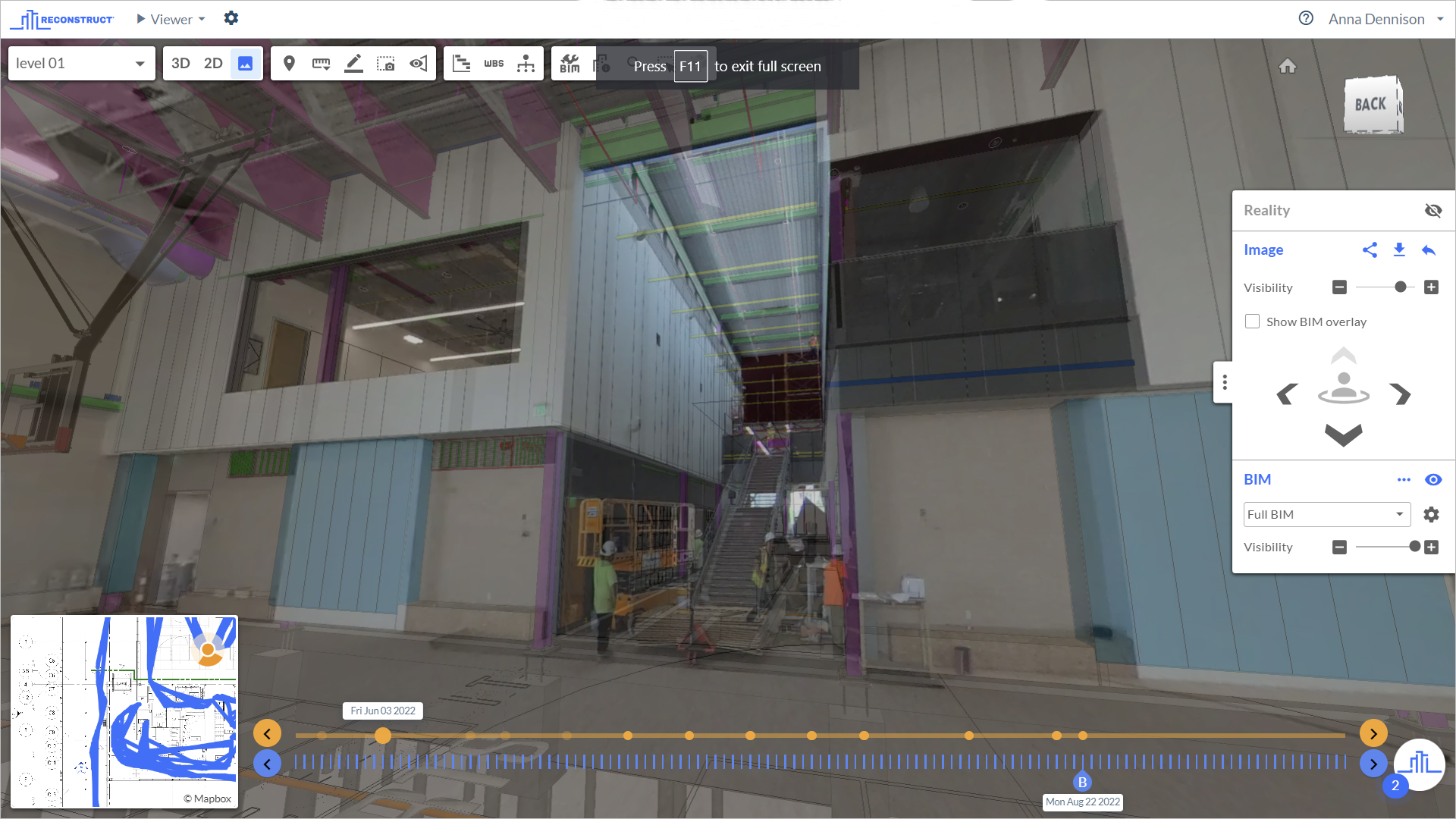

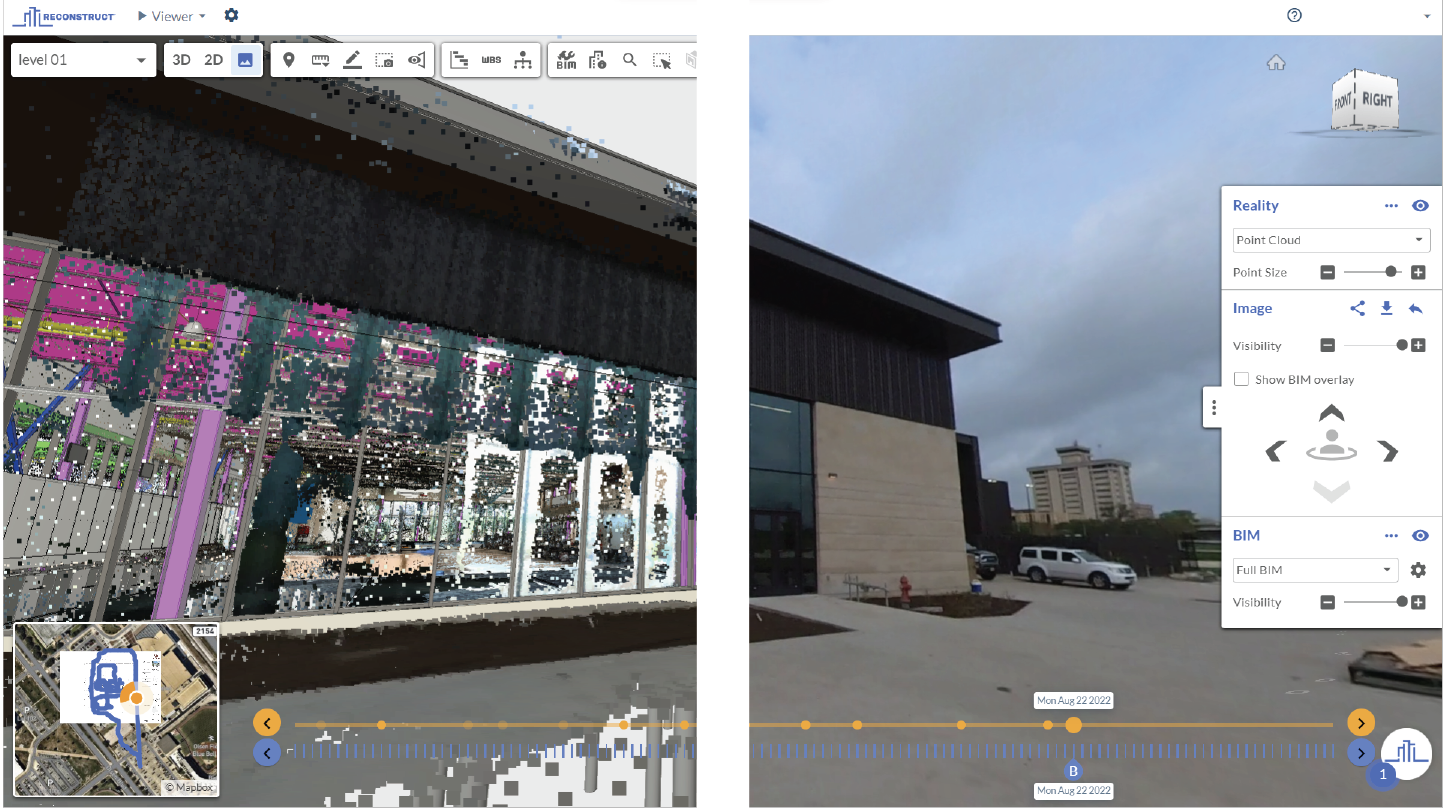

A digital twin is a virtual duplication of a construction project (or finished structure or infrastructure) informed by reality data gathered through devices such as smartphones, 360 cameras, laser scanners, and drones. Using cutting-edge photogrammetry technology, these digital twins are now so realistic and immersive that they rival an on-site, physical walkthrough of an asset.

In this article, we’ll zero in on five of the many challenges solved by the advent of highly accurate, easy-to-generate digital twins across the construction, inspection, and engineering industries.

1. Digital twins enable more frequent construction progress monitoring and quality control

One of the chief benefits of cutting-edge digital twinning is how much easier construction progress monitoring and quality control become for remote stakeholders. All field teams need to do to create a digital twin of an active job site is perform simple reality capture walks with affordable equipment such as smartphones and 360 cameras, then feed the footage to a reality mapping engine.

What's more, reality capture has become easier and easier to perform over the past decade. Today, virtually anybody on the job can conduct a reality capture walk using software like Reconstruct. With a 360 camera, up to 1,000 square feet can be captured in a single minute. There is no need to turn around and focus on every little corner of the project, either. 360 cameras automatically capture panoramic data as you move through the construction site.

Drones are helpful at grabbing footage of hard-to-reach or unsafe areas, especially exterior shots. Smartphones, which most employees already have on hand, can be used for high-resolution images of complex installations, such as piping or electrical wiring. Unlike other reality mapping engines, Reconstruct combines all the footage to create one digital twin of a project in space and over time. Every time your team performs a new capture, the updated footage is added to the digital twin.

This means that even if your project monitors and quality control stakeholders are half a world away, they can frequently review the updated digital twin as if they were on the job site. Perhaps, in the past, they'd only be able to perform such walkthroughs in person a handful of times. Instead, with the help of a digital twin, they're able to inspect construction progress and construction quality as frequently as your team conducts reality capture.

Related: Remote Construction Monitoring: The Key to Building Sweden's Tallest Office Tower

2. Digital twins allow stakeholders to monitor large portfolios of construction projects

As previously mentioned, a digital twin makes frequent construction progress monitoring and quality control much easier for remote stakeholders. After all, they can not only remotely walk the job site as if they were actually there, but they can also use additional features of reality mapping software to compare what's been built against what's been designed and to visualize the next steps of the construction schedule.

This can be especially helpful to portfolio managers tasked with overseeing multiple construction projects at once. For example, in the retail and multi-site space, many regional employees are in charge of construction at dozens of sites and stores that are being rapidly constructed but may span several states.

Now, instead of visiting each site maybe once or twice or keeping up with a grueling schedule that's a whole lot more travel than actual on-site work, these stakeholders can review all the sites in their portfolio in a single afternoon from the comfort of their desks. Of course, travel can and should be scheduled when necessary, but suddenly, a portfolio that seemed impossible to keep up with can be reviewed in a couple of hours.

Related: 3 Construction Pain Points for Retail & Multi-Site Project Managers

3. Digital twins offer the ability to measure job sites precisely but remotely

Next, the best digital twins are also completely measurable—down to a fraction of an inch. Of course, the quality of reality capture affects these accuracies, but in general, 360 capture will give you tolerances within 1%. That means if you're measuring something that’s 100 inches, the digital twin may be off by one inch.

Laser scanning, which is more expensive and time-consuming and typically reserved for as-built documentation, would give you a tighter tolerance: accuracy within 1/16 of an inch.

But the fact that 360 capture can get you so close—especially for everyday quality control, project monitoring, and schedule visualization—is well within the tolerances of most stakeholders. And, what’s more, measuring doesn’t need to be done on the spot, either. Instead, stakeholders can measure at their desks, armed with all the resources required to generate actionable insights.

4. Digital twins enable stakeholders to overlay design, visualize schedule, and rewind the construction clock

When you perform an in-person walkthrough of a job site, there are many obvious benefits: chatting with field teams, inspecting work in progress, and seeing the construction conditions and quality for yourself. But, with the help of construction visualization software, all of this can now be done virtually, too—and far more frequently and with fewer resources.

Plus, certain technology-enabled features simply cannot be done in the real world, including:

- Overlaying 2D and 3D designs and plans atop the digital twin to compare what’s been built vs. what’s been designed.

- Visualizing the next steps of the construction schedule atop the digital twin to plan next steps, increase project understanding, identify conflicts, and more.

- “Rewinding” construction to any date or time to visualize construction as it was in the past—which is perfect for “seeing through walls” or “un-pouring concrete,” actions that would, in real life, cost a fortune and slow down construction dramatically.

5. Digital twins arm all stakeholders with a single source of proper truth

One of the chief issues with construction, inspection, and engineering stakeholders is that all parties are rarely on the same team (or in the same place at the same time). One contractor is here; another owner’s representative is 5,000 miles away. But now, with the advent of digital twins, all stakeholders from all organizations can communicate about and collaborate on one single, irrefutable source of project truth.

This unprecedented visibility empowers all stakeholders from all sides to come together to focus on completing projects on time, on budget, and as planned…even if it’s impossible for all parties to physically meet simultaneously. Best of all, this collaboration can be done at a fraction of the cost—with a digital archive that can answer questions for years and years to come.

About Reconstruct

Reconstruct has set the gold standard for digital twins across the construction, inspection, and engineering industries. To see how easy it is to capture job site footage and transform it into an accurate, measurable digital twin, schedule a personalized demo today.

.png)

.png)