Why is site inspection important in construction and engineering?

Construction and engineering site inspections almost always happen because they are required by law. After all, once construction on a project is complete, the need for constant construction progress monitoring is gone. Instead, stakeholders will often perform as-built documentation and then perform site inspections at regular intervals as required by law.

Rules and regulations about the frequency and requirements of each inspection vary from state to state and country to country. Still, regardless of location, the highest-risk facilities (such as nuclear reactors or high-rise buildings positioned near key bridges) must be inspected at the most frequent intervals.

This is also true for structures and infrastructure that pose high risks and offer strategic value. Examples include power plants, water treatment facilities, and more. These are projects that have very frequent inspection schedules. After all, should a structural failure or leak occur, these facilities would need to be shut down, and there may be environmental impacts. These are all examples of what one might call tier-one inspection projects.

But, after these key strategic structures, inspection tends to happen less frequently. Think: commercial buildings and residential high-rises. This trend continues down to single-family homes, where many buyers do not even perform an inspection.

That said, many organizations perform more frequent inspections than the law requires. The key reason here would be maintenance. In other words, interim inspections allow organizations to catch minor problems before they snowball into expensive maintenance requirements. For example, frequent inspections may help stakeholders notice rust on a beam that can be addressed on the spot. However, had it taken five more years to notice this, the entire beam might have been compromised and would be in need of an (expensive, disruptive) replacement.

What are the benefits of using reality mapping for site inspection?

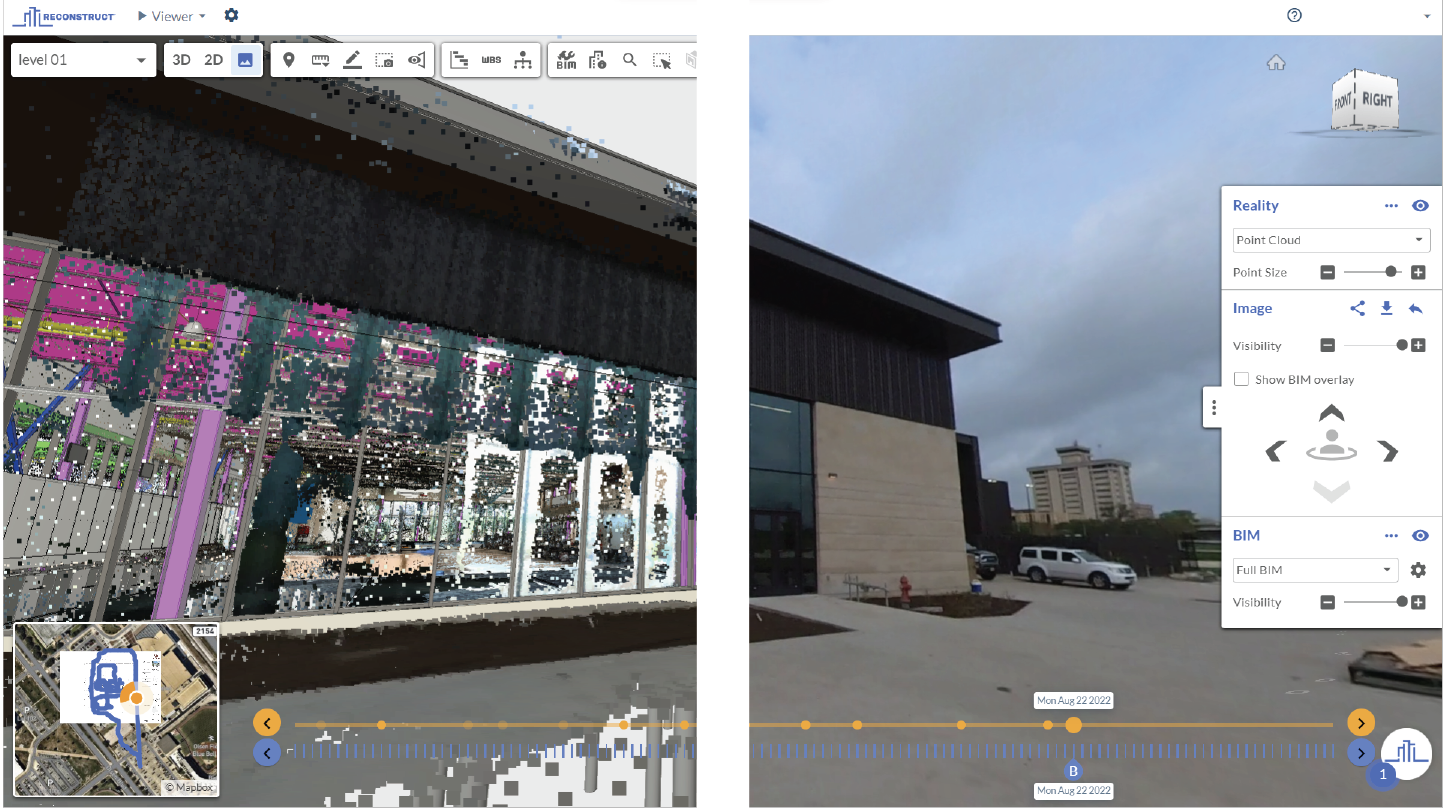

When an inspection is required, an organization will typically reach out to either external or internal experts who can travel to the site and perform a professional inspection. These stakeholders, who are almost always engineers, report their findings to the key stakeholders. With Reconstruct, some inspections can be performed remotely. That is, footage can be captured on-site using a variety of hardware and then interpreted by an expert at a remote location.

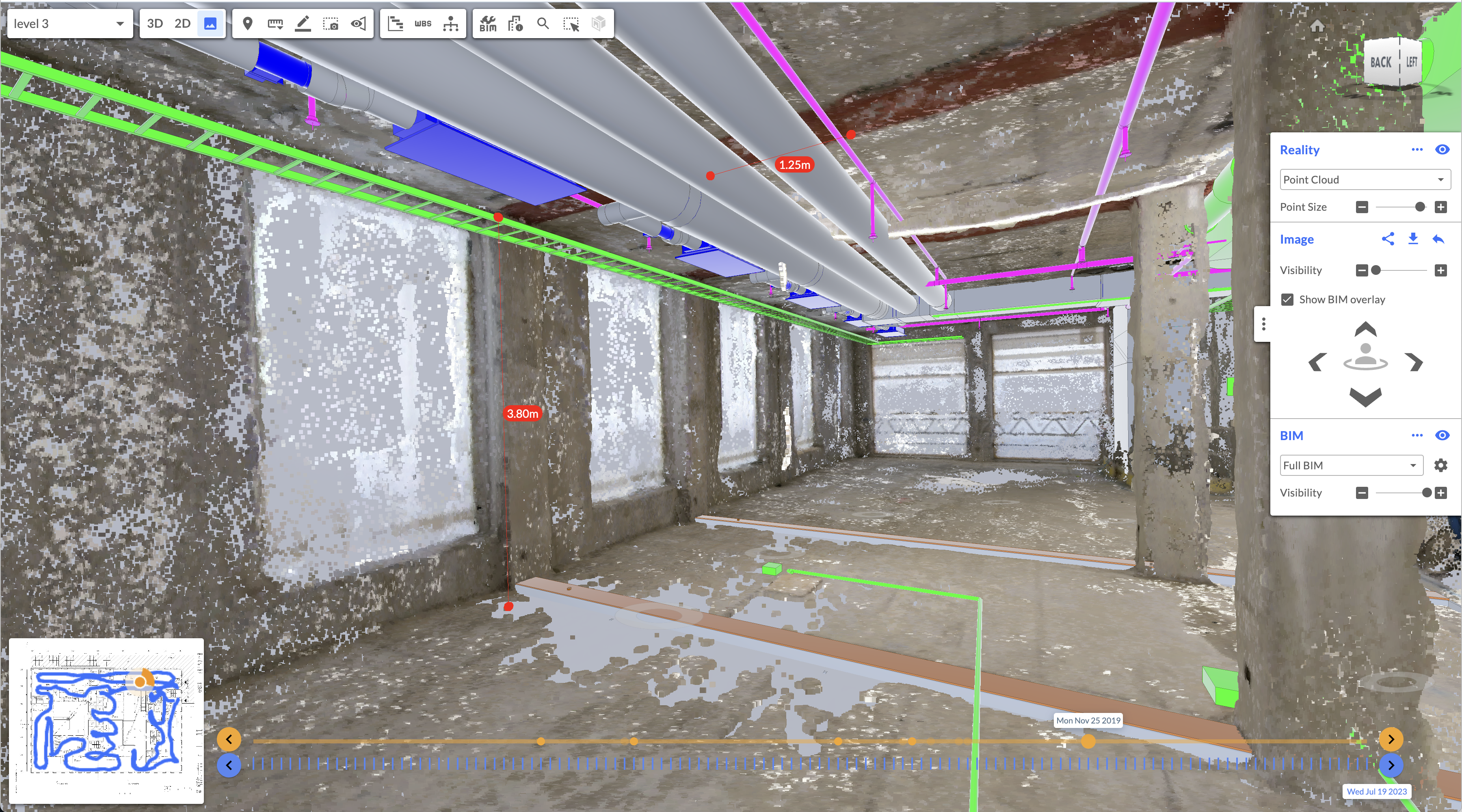

Of course, unlike frequent reality capture for construction quality control, there are almost always restrictions about who can perform an inspection in this situation. However, there are still key benefits to utilizing reality mapping software during inspection. The chief advantage is that inspectors can create a virtual duplication of everything they see that can later be fed to a photogrammetry engine like Reconstruct. The reality mapping engine can then rapidly transform all inspection footage into a digital twin of this structure or site.

Stakeholders can then look back to that footage to consider changes to a structure over time. Such documentation can also answer questions during tenant improvements or even fend off liability claims. For these reasons, many building owners maintain digital twins with Reconstruct years after inspections are performed.

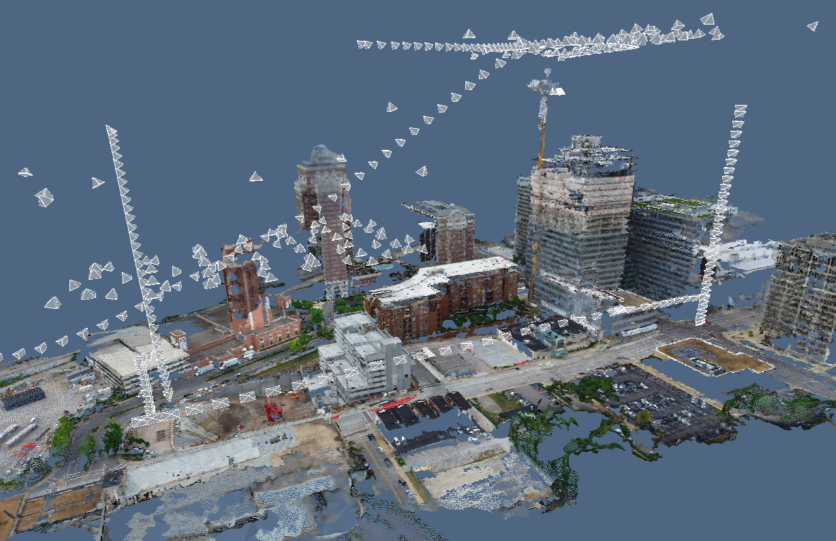

Reality mapping can also help site inspectors better understand current conditions in hard-to-reach or potentially unsafe areas. From inside tunnels to the tops of football stadiums, drones and other robotic devices can capture footage that informs site inspectors' safety and next steps.

Reality capture data can also be used to compare what's there against what should be there via 2D and 3D design integration.

About Reconstruct

Reconstruct is the leader in digital twins for construction, inspection, and engineering. By allowing virtually any team member to capture reality data using any device, including a smartphone, 360 camera, drone, or laser scanner, it's never been easier to create a virtual duplication of a construction project.

Along every touchpoint of the construction lifecycle, stakeholders can utilize Reconstruct’s intuitive reality mapping software to rapidly capture and share as-built footage of the job site in space and over time. From current conditions assessments to frequent project monitoring to construction quality control to as-built documentation to post-construction site inspections, Reconstruct allows stakeholders to capture every inch of the job site.

To learn more about site inspection and how reality capture can make the process easier and more efficient, schedule a personalized demo of Reconstruct today.