It's no secret that airports are virtually always under renovation. Even when full-fledged construction is not underway, those airports are, at the very least, undergoing some maintenance. A new food court is being installed, an entire terminal is being revamped, or a runway is being repaved…

Regardless of what sort of construction, maintenance, or renovation an airport is currently undergoing, a digital twin for construction can make the process faster, more accurate, and more collaborative. This article will focus on how, with the help of a digital twin and its quality control and reporting features, more and more stakeholders can easily work together to ensure construction and maintenance are completed in the fastest, safest, and most accurate way.

Airports are complicated, and modeling them creates transparency and clarity

Airports are widely considered some of the most complicated construction projects. They are not only massive but highly regulated and must be built exactly to specifications, like healthcare facilities. Additionally, airport construction is expensive—and there are a lot of eyes on the job, too. For these reasons, more and more airport stakeholders are keen on using the best technology available to improve as-built documentation processes.

This is why, over the past decade, many construction management firms and other stakeholders have begun using reality capture to regularly record and monitor construction progress and maintenance at airports. At the most basic level, frequent recording—which can be performed by all sorts of devices, from laser scanners to smartphones to 360 cameras—creates a digital record of all construction and renovation in space and over time.

This empowers both maintenance of airport facilities after construction is completed and quality control and construction progress monitoring during rebuilds and renovations. Additionally, a digital twin allows stakeholders to see through walls without the disruption and financial toll of demolition. Instead, the stakeholder can simply rewind the construction clock with the click of a button to visualize how the airport looked at any given date or time when reality capture was performed.

Features such as BIM overlay allow increased visibility into defects, schedule progress

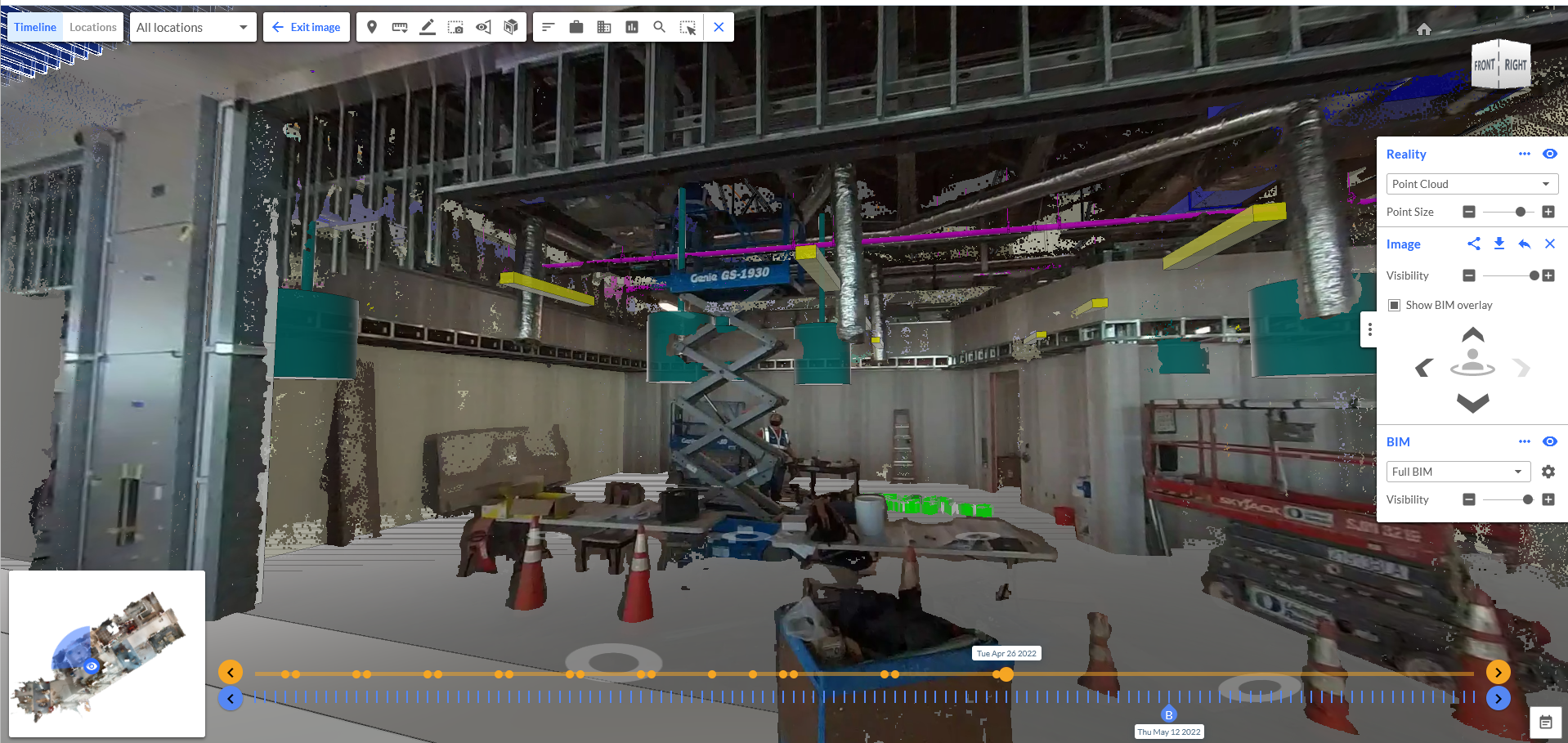

Additionally, an exceptional photogrammetry engine can provide stakeholders with highly immersive, photorealistic, and measurable 3D reality data. This digital twin can be synced with the construction schedule so all stakeholders can align on what will be built and when.

The digital twin immediately functions as a single source of project truth for a highly complex project. It enables all coordinators, from the head of the construction management firm to even the most siloed of trades, to work together to ensure that all aspects of construction are moving along as planned and that the construction itself matches designs and drawings.

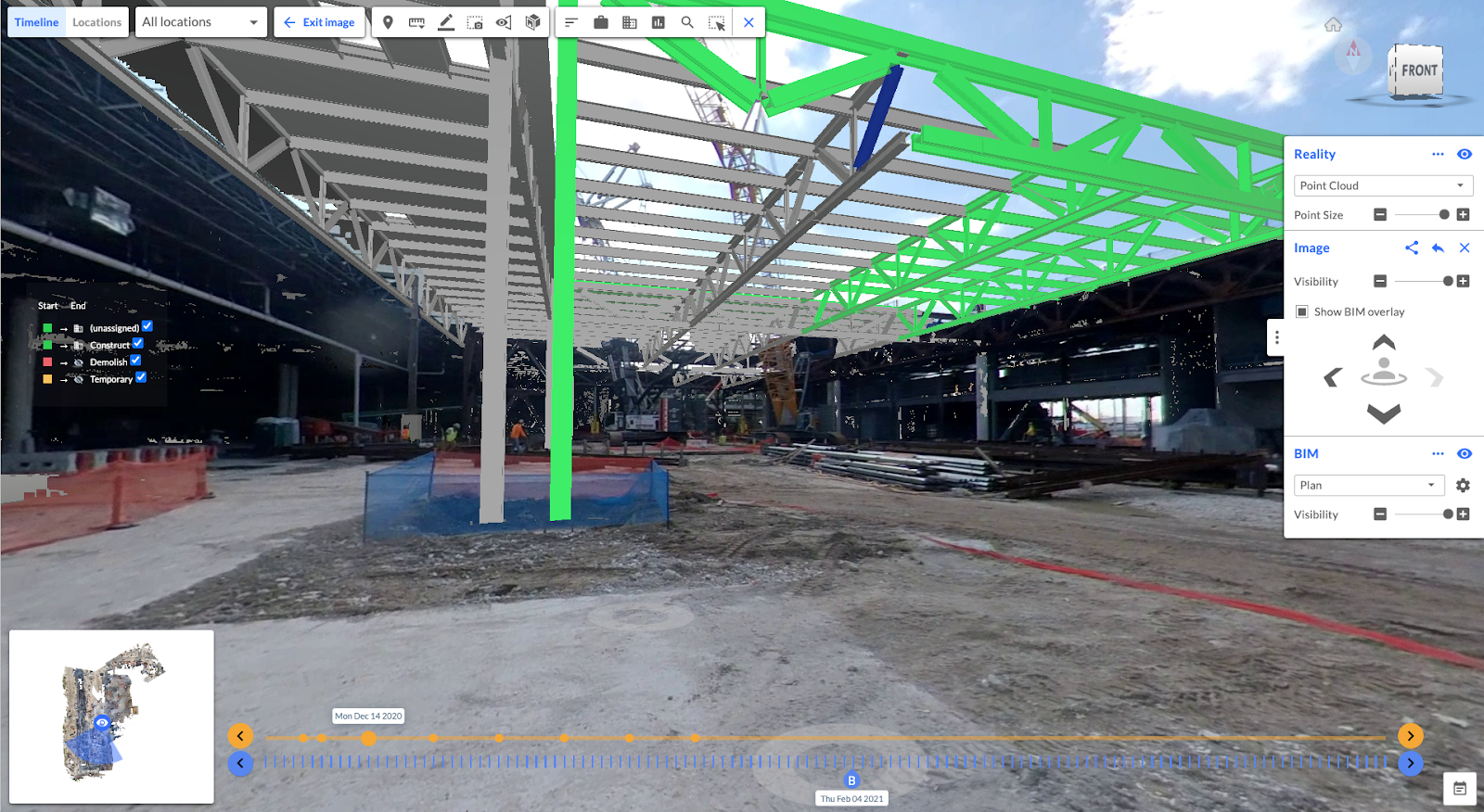

For this, a feature that enables stakeholders to overlay design drawings and BIM atop reality data is essential. With Reconstruct, stakeholders can simply compare what's been built against what's been designed to swiftly identify deviations in construction and make corrections to either the construction or the plans immediately. Additionally, all such concerns and correlated resolutions can be documented directly onto the digital twin, automatically creating an archive of how problems were identified and handled.

Reality mapping (and digital twins for construction) helps with model accuracy, making sure that the model is true to what was built and that what was built is true to the model. Reconstruct’s ability to overlay a point cloud to a BIM helps highlight mistakes that are not allowable or need to be modeled back into the original model.

In an airport setting, it's not unusual for stakeholders to meet daily to review reality data and coordinate the next steps of construction. With the help of a digital twin, stakeholders have more information and reality data at their fingertips than ever before. The end result is a more transparent and aligned approach to airport construction that saves time and money for all parties.

About Reconstruct

Reconstruct has set the gold standard for digital twins in airport construction and maintenance. It allows stakeholders to create 3D site surveys and 2D floor plans using virtually any type of reality capture device. All footage can be blended together to create one single, timestamped source of construction truth.

To see your airport construction project in Reconstruct, schedule a personalized demo today.

.gif)