Compare design against existing 360 and drone reality capture

Over the past few weeks, we've written two articles that zeroed in on Reconstruct’s ability to transform existing reality capture from 360 cameras and drones into 2D floor plans and 3D reality models of your project as-built. What's more, Reconstruct can blend footage from virtually any device, allowing your team to pick the best (and most reasonable) tool for reality capture, given the resources available, at every point along the construction timeline.

That means if you've already performed reality capture, even years ago, it's always possible to transform that data into a digital twin of your job site. These digital twins for construction, engineering, and inspection stakeholders can be used for virtually every use case, including protection against claims and litigation, visual progress monitoring, physical asset inspections, site surveys, facility condition assessments, and comparing what's been built against what's been designed.

This article will focus on the benefits of using existing, blended geo-referenced reality capture data for 2D and 3D design integration.

Why bring all reality data together?

Most reality capture “viewers” can only host footage from a single type of device. That means that any reality data captured via 360 camera must be viewed separately from footage captured via drone, laser scanner, or Matterport device.

While this is a common way to view geo-referenced reality data, it's certainly not the easiest or the most accurate way to visualize a job site. Fortunately, Reconstruct allows stakeholders to blend any and all forms of reality data to create one digital twin that offers a photo-realistic, measurable walk-through of a building or asset in space and over time.

If your team has been using 360 cameras for frequent project monitoring, drones for exterior capture, smartphones for in-depth, high-resolution photos of complex installations, and laser scanners for final project documentation, it's not too late to bring all of that data together into one single, immersive representation of your asset.

By blending all existing reality data from every device into one single, timestamped source of project truth, Reconstruct enables everything from remote project monitoring to visual quality assurance and quality control—without ever stepping foot on the job site.

The benefits of integrating design and reality data

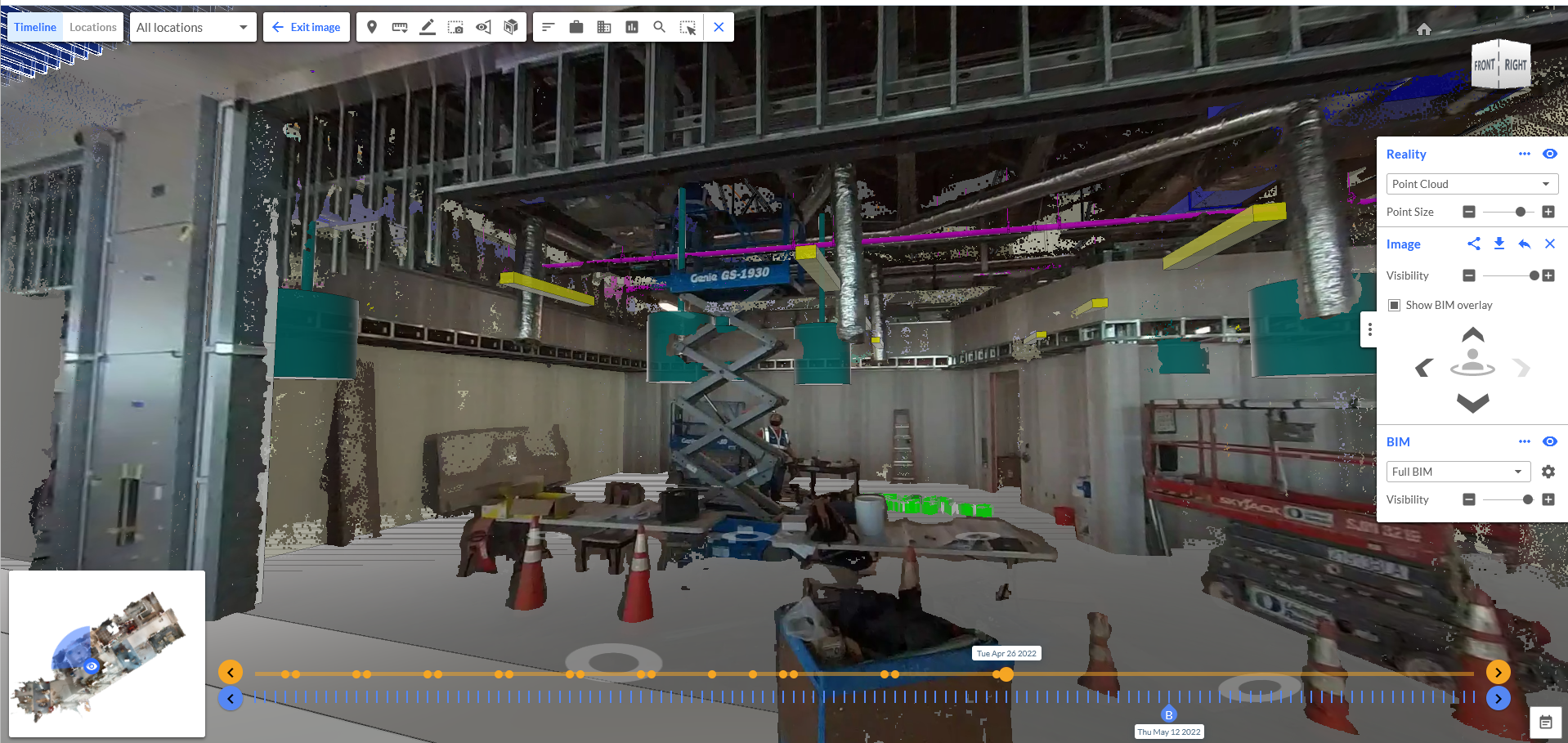

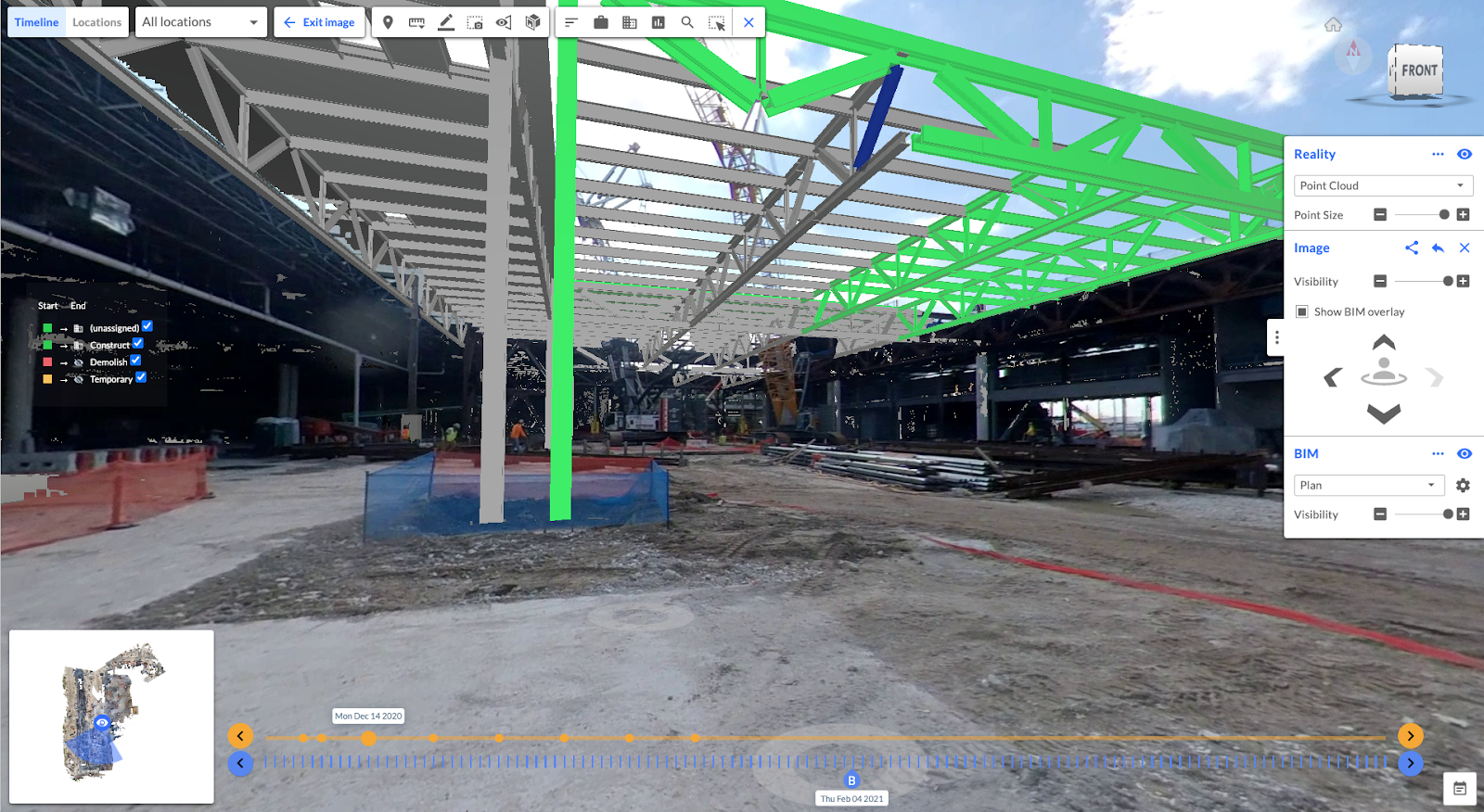

Once you combine all reality to create one single source of project truth, it's suddenly much easier to compare what's been built against what's been designed and planned. Reconstruct allows users to overlay virtually any design drawing or BIM atop the digital twin, enabling remote stakeholders to immediately visualize any deviations from the plan, ask questions, and act accordingly.

This design-vs.-reality feature allows teams to:

- Communicate design to field teams, then coordinate who does what work by reviewing the most updated state of the project against design and plans.

- Remotely monitor work, performing safe and effective visual quality assurance and quality control, RFI documentation, safety inspection, and punch lifting without traveling.

- Maintain visibility of project execution from anywhere in the world, looking into every deviation to understand and approve design changes.

In the event this design-vs.-reality comparison yields unexpected deviations, Reconstruct’s communication tools allow stakeholders to quickly identify problems, ask questions, and resolve issues. Communication is automatically documented should questions arise in the future.

Moreover, Reconstruct also serves as a time machine for construction, enabling stakeholders to rewind the clock and visualize an asset at a given date and time—without the need for costly demolition.

To learn more about turning your existing reality data into a digital twin, contact us for a free demonstration.

.gif)