How reality mapping makes remote infrastructure inspection easier

Today, reality mapping technology can be used to capture data about not just buildings and assets but infrastructure, too. From tunnels to airport runways to power plants, more and more construction, engineering, and inspection stakeholders are utilizing photogrammetry to create virtual duplications of infrastructure.

In this article, we will zero in on the unique challenges of capturing infrastructure and how the right reality mapping technology can make the process easier, faster, and more economical.

Three unique challenges of remote infrastructure inspection

When it comes to reality capture and physical inspection, infrastructure is not as simple to record or walk as a building or similar structure. The infrastructure itself may be miles long, deep, or wide. It may also be below ground, difficult to access, and very poorly lit.

Moreover, many infrastructure projects, including electricity, sewage, and roads, tend to be linear: they go on for miles and miles. And so, the first unique challenge of infrastructure reality capture is access. Stakeholders may wonder how they can cover such a considerable distance when performing reality capture and what tools are the best bet for such a lengthy capture, especially if access to the infrastructure is limited.

The second challenge for remote infrastructure inspection is often lighting. If you're digging a trench and laying pipes in there, this won’t be an issue: you'll simply capture data during the morning when the light is good. But if you're working on a utility project in a tunnel, there's no good lighting available to you at any time of day. As a result, you'll need to install artificial lighting and figure out how to handle that lighting during reality capture.

Sometimes, people performing reality capture will carry a powerful light that illuminates whatever is currently being captured. Other times, stationary lights are placed along the length of the tunnel (or other infrastructure), enabling not just reality capture but safer and more efficient working conditions. Reconstruct often works with its customers to help figure out the best solution for lighting during reality capture.

Finally, the third challenge is all about resolution, tolerances, and accuracies. After all, different reality capture devices deliver different results and different levels of accuracy and measurability. What tools need to be used depends on the stakeholders' tolerances, budget, and—as previously mentioned—their accessibility to the infrastructure and how well they can illuminate it. Accuracy will also be affected by how close your team members can get to a given aspect of the project.

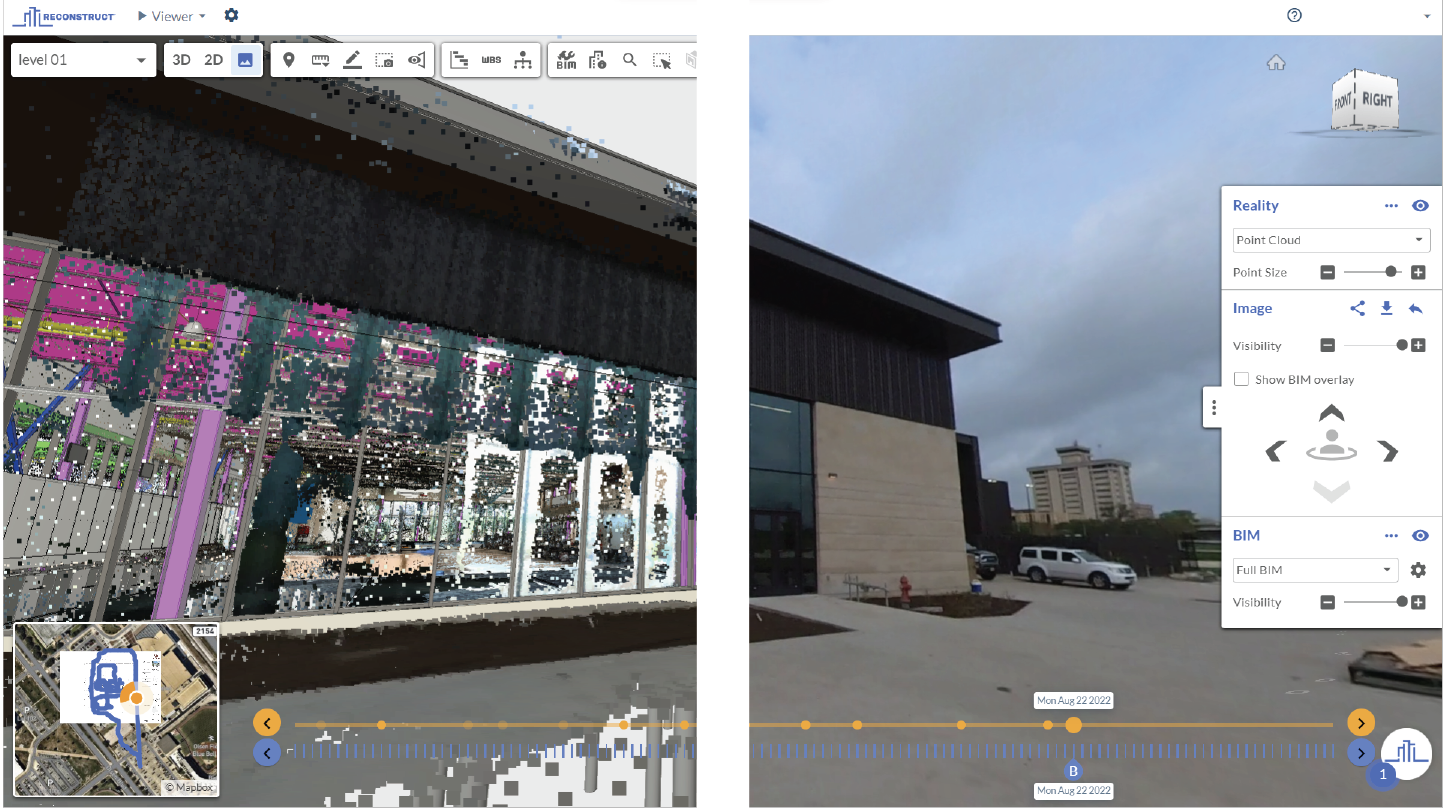

Fortunately, Reconstruct’s reality mapping engine allows stakeholders to combine footage from all different types of devices, ensuring that high-resolution images are blended with more broad 360-footage as needed.

For example, if you're working on important utility work, you may want to use a smartphone for up-close, high-resolution images of pipes. The same goes for electricity: you'll want to capture up-close, high-resolution pictures to pick up on part numbers for transformers and so on.

Of course, with the help of Reconstruct, these detailed images can be blended with any other footage captured to create one single source of project truth that shows infrastructure in space and over time.

Being able to combine reality data from a variety of sources is often very helpful for organizations tasked with overseeing infrastructure construction, inspection, maintenance, or repairs. For example, a team member may drive the length of a project using a 360 camera to capture footage mile after mile. That footage can then be combined with up-close smartphone snapshots of key installations.

For the most accurate measurability, laser scanner documentation can also be combined with other footage. However, in many cases, the use of a simple, fast, and affordable 360 camera (combined with smartphone photos, if necessary) can provide stakeholders with frequent and immersive footage of infrastructure that can be used for a variety of purposes, including remote site inspection.

About Reconstruct

Reconstruct’s reality mapping engine has set the gold standard for digital twins across the construction, engineering, and inspection industries. To learn more about how to capture your infrastructure project using Reconstruct, schedule a personalized demo with our team today.