Remote Quality Control: The Secret to Avoiding Costly Rework

By nature, the construction industry uses many resources to build, renovate, and maintain buildings and structures. Still, whether due to defects or rework, up to ten percent of construction materials wind up wasted. It doesn’t have to be this way. Remote quality control tools such as reality mapping can help eliminate unnecessary resource burn… or even prevent defects and rework in the first place.

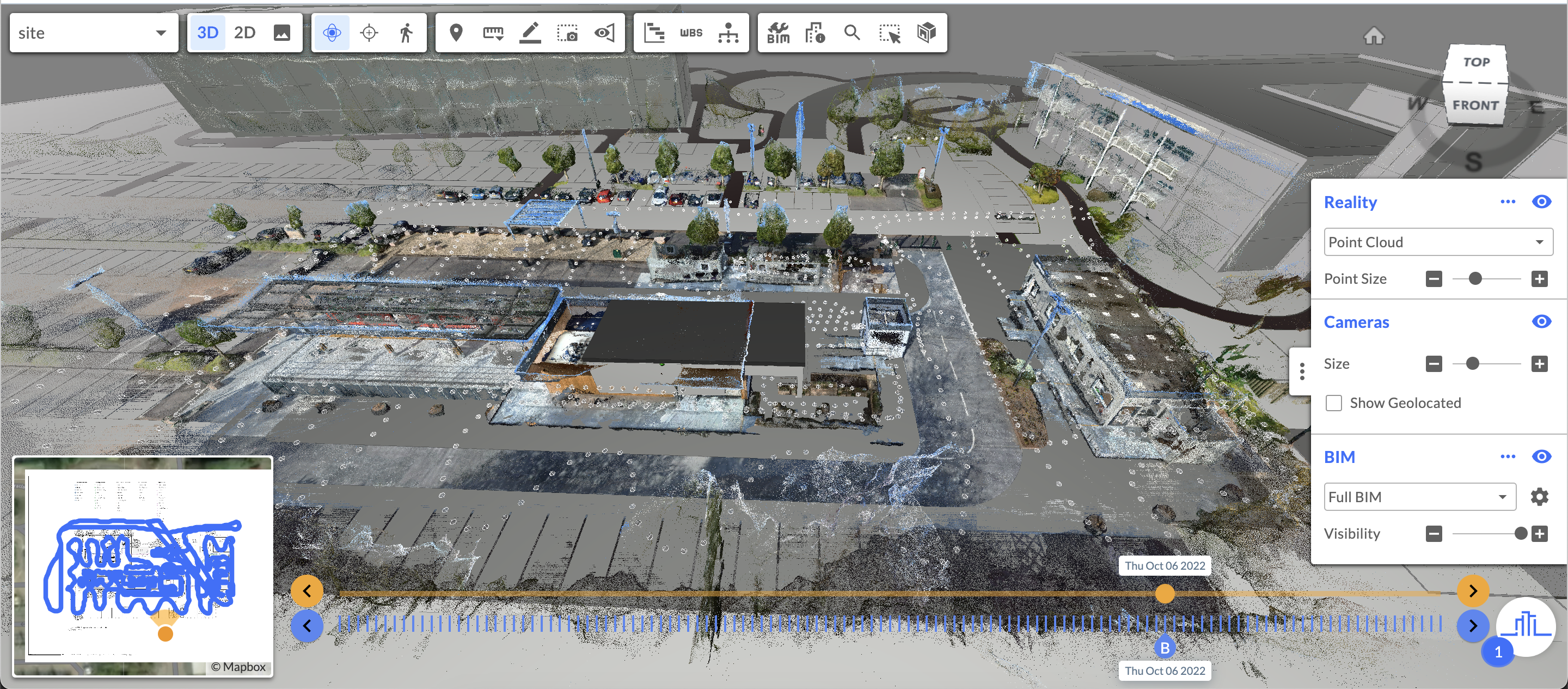

Regardless of the physical distance between on-site construction and operations teams and remote stakeholders, reality mapping erases the disconnect between teams by creating a shared, consistent, realistic 3D experience of a project. In addition, stakeholders can use reality mapping data to conduct remote walk-throughs, re-inspect previous work, conduct visual quality assurance and quality control, clarify confusion about next steps, and even overlay design drawings and BIM to identify actual or potential quality concerns.

In this article, we’ll zero in on how reality mapping technology can vastly improve remote quality control efforts throughout a building’s lifecycle, saving all stakeholders time, stress, and money—especially when it comes to rework.

Reality mapping technology is finally efficient and accessible

In the past, stakeholders needed laser scanners and highly-trained, on-site experts to capture construction progress. But breakthroughs in Reconstruct’s reality mapping technology have enabled existing, on-site teams to rapidly capture construction progress using affordable, everyday technology like smartphones, 360 cameras, and drones. Once reality capture is complete, Reconstruct’s engine generates a truly immersive walkthrough of a job site, along with 3D models and 2D floor plans of what’s been captured.

These reality maps are automatically configured and highly accurate, allowing even remote stakeholders to measure the tiniest corners of a construction project down to the centimeter—or even the subcentimeter. And because reality capture with a smartphone, 360 camera, and drone is more efficient and less expensive than laser scanning, it’s much easier for teams to keep up with reality capture walks, conduct visual progress monitoring, improve communication with off-site teams, and reap the benefits of frequent quality control inspections.

While there is a time and a place for laser scanning, most stakeholders find that a quick reality capture using everyday equipment provides quite a sharp lens for remote quality control. Using Reconstruct’s digital twin of a construction site, stakeholders can catch quality control issues before these mistakes turn into costly rework and jeopardize the project’s timeline or budget.

Related: Choosing the Right Reality Capture Tool, Process & Team

Reality mapping is highly accurate, measurable, and rewindable

Once Reconstruct has consumed reality capture data, it uses photogrammetry technology to produce a 2D reality map and a 3D reality model of a building or structure. Since these digital assets are virtual replicas of actual, as-built structures, even remote stakeholders enjoy a truly precise view of a project as it stands today and as it appeared throughout the construction timeline.

Benefits of mapping, walking, and measuring the digital twin include the ability to:

- Compare as-built work against as-planned work, including design drawings and BIM.

- Verify the placement of openings, embeds, rebar, concrete sleeves, etc., before proceeding with wall closures, concrete pours, and other resource-intensive tasks prone to costly rework.

- Audit quality control findings collaboratively, with all teams reviewing the same, timestamped source of geo-referenced reality capture.

- Using Reconstruct Project Snapshot, create an accurate archive of all construction history so stakeholders can rewind progress to peek beneath floors or see through walls without costly demolition.

Reality mapping allows instant overlay of a project as-built vs. as-designed

Construction stakeholders know that what’s been planned on paper isn’t always what ends up built. But within Reconstruct’s Visual Command Center, even off-site stakeholders can remain apprised of such deviations during regular, remote quality control checks. Users can simply overlay plans atop as-built reality mapping, reducing or eliminating site visits while inspecting work and offering actionable insights regarding whatever concerns they discover.

Stakeholders can also overlay 4D BIM against 3D reality to visualize whether key construction elements have been improperly placed. For example, many stakeholders insist on overlaying BIM before each concrete pour so that quality control can be performed before the risk of costly rework skyrockets.

Reality mapping delivers value along every step of the construction lifecycle

Whether a project is approaching demolition, halfway through construction, or finally complete, reality mapping technology enables resource-saving, rework-preventing quality control. From the start, stakeholders stationed even half a world away will have precise, updated 2D and 3D digital twins of a construction site. These assets can be used to search for problems, improve communication, and reduce the likelihood of future mistakes. What’s more, reality mapping drastically reduces—and, in some cases, eliminates—the need for extensive business travel and on-site walkthroughs. After all, remote and on-site workers now share the same as-built digital twin, creating one accurate asset with which all stakeholders can monitor progress and discuss quality control together.

And finally, even when construction winds down on a job site, a reality map creates an archive of a project as it was built over time. So instead of demolishing a wall to verify what’s behind it, stakeholders can simply turn back the clock on the digital twin of their project, saving on costly rework time and time again.