For years, 3D scanning has been used by construction, inspection, and engineering stakeholders to create a virtual duplication of the job site to be used for a variety of purposes, from as-built documentation to construction quality control. In this article, we’ll define 3D scanning and review its top benefits for various stakeholders.

What is 3D scanning?

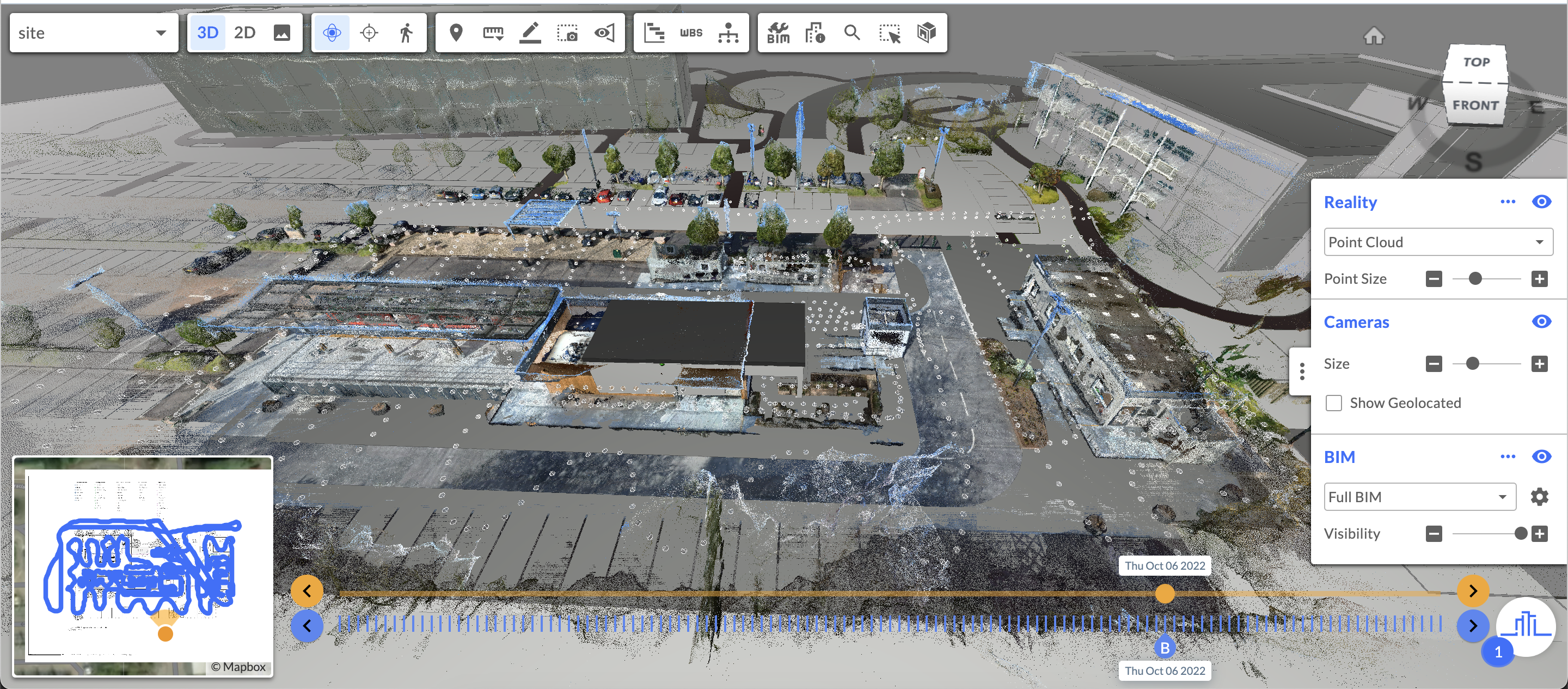

In construction, 3D scanning refers to the process of capturing the reality of a structure (or infrastructure) and then creating a digital version of the asset that's three-dimensional. Over the past decade, this technology has grown increasingly popular--and increasingly cutting-edge. In fact, Reconstruct’s reality mapping engine can create a digital twin of a job site so realistic it's comparable to an on-site walk-through and measurable to a fraction of an inch.

What’s more, photogrammetry technology can improve the accuracy and efficiency of construction while ensuring projects are completed on time and on budget. Also known as a current conditions assessment or site survey, 3D scanning is an essential part of remote progress monitoring, a strategy whose success relies on cutting-edge reality capture devices and reality mapping software.

What are the best tools for 3D scanning of a construction site?

The best hardware for a 3D scan of a construction site varies depending on a whole host of circumstances, from weather to budget to time constraints. In fact, Reconstruct partnered with Oracle Labs to test out precisely what tools and teams are best for which reality capture use cases in a first-of-its-kind experiment.

In general, the consensus is that:

- Laser scanning is highly accurate but rather slow and quite expensive. Laser scanning is commonly used for the final documentation of a construction site.

- 360 cameras are reasonably accurate, capture quickly, and are low cost. They are perfect for frequent construction progress monitoring capture where a panoramic view is essential.

- Smartphones are accurate, capture relatively quickly, and are low-cost. They are perfect for high-resolution captures of key installations and in-wall inspections.

- Drones are accurate, capture very quickly, and at a relatively low cost. They are also perfect for the outdoors or other hard-to-reach or otherwise unsafe areas.

|

Tool

|

Laser Scanning

|

360 Cameras

|

Smartphone

|

Drone

|

|

Accuracy

|

xxxx

|

xx

|

xxx

|

xxx

|

|

Speed

|

x

|

xxx

|

xx

|

xxxx

|

|

Cost

|

xxxx

|

x

|

x

|

xx

|

Note that, unlike other reality mapping solutions, Reconstruct’s photogrammetry engine blends footage from any and all devices, which means you can combine point clouds, images, and videos captured on laser scanners, 360 cameras, smartphones, drones, and Matterport devices to create a single source of project truth, in space and over time.

The resultant digital twin for construction can be used for virtually every use case, including current condition assessments, remote project mentoring, construction quality control, and as-built documentation.

Benefits of 3D scanning for construction

The top benefits of performing regular 3D scanning of a job site include:

1. Saving time and money

Often, stakeholders tasked with managing or inspecting construction progress, installations, or current conditions have an extensive list of sites to manage. By empowering teams with 3D scanning, stakeholders can remotely keep an eye on current conditions at all properties, and then intelligently select sites that require in-person observation.

This is also true for regular progress monitoring, where weekly travel to every job site might be impossible, but a virtual review of all sites in a portfolio could reasonably be performed in a single afternoon from the comfort of a stakeholder’s office. Of course, travel for in-person inspections can still be scheduled whenever necessary.

Stakeholders can also leverage 3D scans to make OAC and weekly coordination meetings more efficient. Features such as Reconstruct’s Project Snapshot allow stakeholders to curate pre-planned tours of the job site that zero in on only the updates attendees need to see.

2. Protecting against claims

When 3D scanning is performed regularly and processed by a photogrammetry engine such as Reconstruct, a digital twin of the job site is archived, in space and over time. In other words, stakeholders maintain a virtual record of construction progress from day one and can rewind the clock at any time to answer liability claims and tenant questions without the cost of demolition or litigation.

3. Keeping teams safe

3D scanning can also keep teams safe, especially when areas are hard to reach, at high elevation, or otherwise high risk. Instead of sending surveyors or members of a field team to these spaces, other capture devices can be used to record footage that can be reviewed remotely.

.gif)

.png)