360 Progress Capture: Creating a Digital Twin for Remote Construction Monitoring

It's no secret that more and more businesses are relying on remote construction progress monitoring to improve project outcomes. With the help of cutting-edge reality mapping technology, project stakeholders are enjoying unprecedented visibility into construction without the hassle or expense of constant travel to the job site.

The 360 camera has made construction progress monitoring more accessible than ever before. These cameras are affordable and easy to use, which means that virtually any employee on the job site can utilize one to perform frequent 360 reality capture. In this article, we will zero in on how 360 cameras can be used for frequent project monitoring and construction quality control.

The basics of 360 capture

As we discussed in our guide to 360 cameras, 360 capture devices are inexpensive that capture virtually everything. The 360 camera represents the best of both worlds: a reasonable price and the ability to capture immersive, unextracted 360° views of the job site. The third benefit—and a major draw—of the 360 camera is speed. It can capture reality data at a remarkably fast rate.

Laser scanning, on the other hand, is incredibly accurate, but it takes a very long time. With 360 capture, a convenience store can be captured in about 10 minutes. That means virtually every job site can be captured weekly, should the stakeholders request the footage. If you used laser scanning to capture weekly progress, your team would never stop scanning. By the time it had completed scanning for one week, it would be time to scan the next. But with 360 capture, the process is quick, allowing field teams to grab footage and then get back to work.

Of course, there are other reasons why stakeholders would never use laser scanning for frequent construction progress monitoring: the cost, for one, and also the fact that laser scanning must be performed by an expert.

Benefits of 360 progress capture

Because capturing job site progress with a 360 camera is so easy, it unlocks many benefits for organizations implementing the strategy. In construction, inspection, and engineering, progress monitoring occurs when stakeholders monitor actual performance on the ground and then apply those updates to the master schedule, then analyze that schedule to come up with insights about the project's status.

Before the advent of reality mapping, somebody would need to go to the job site and review the schedule against the physical project via an in-person walkthrough. When the tour was complete, this stakeholder would go back and review the activities one by one, marking how complete each task was at a given time in a percentage. These percentages would then be combined to calculate a project status.

One of the chief benefits of 360 progress capture is that all these steps and calculations can be performed from the comfort of the progress monitor's office. This is especially helpful if the stakeholder manages multiple projects, budgets are tight, or frequent travel is simply not possible.

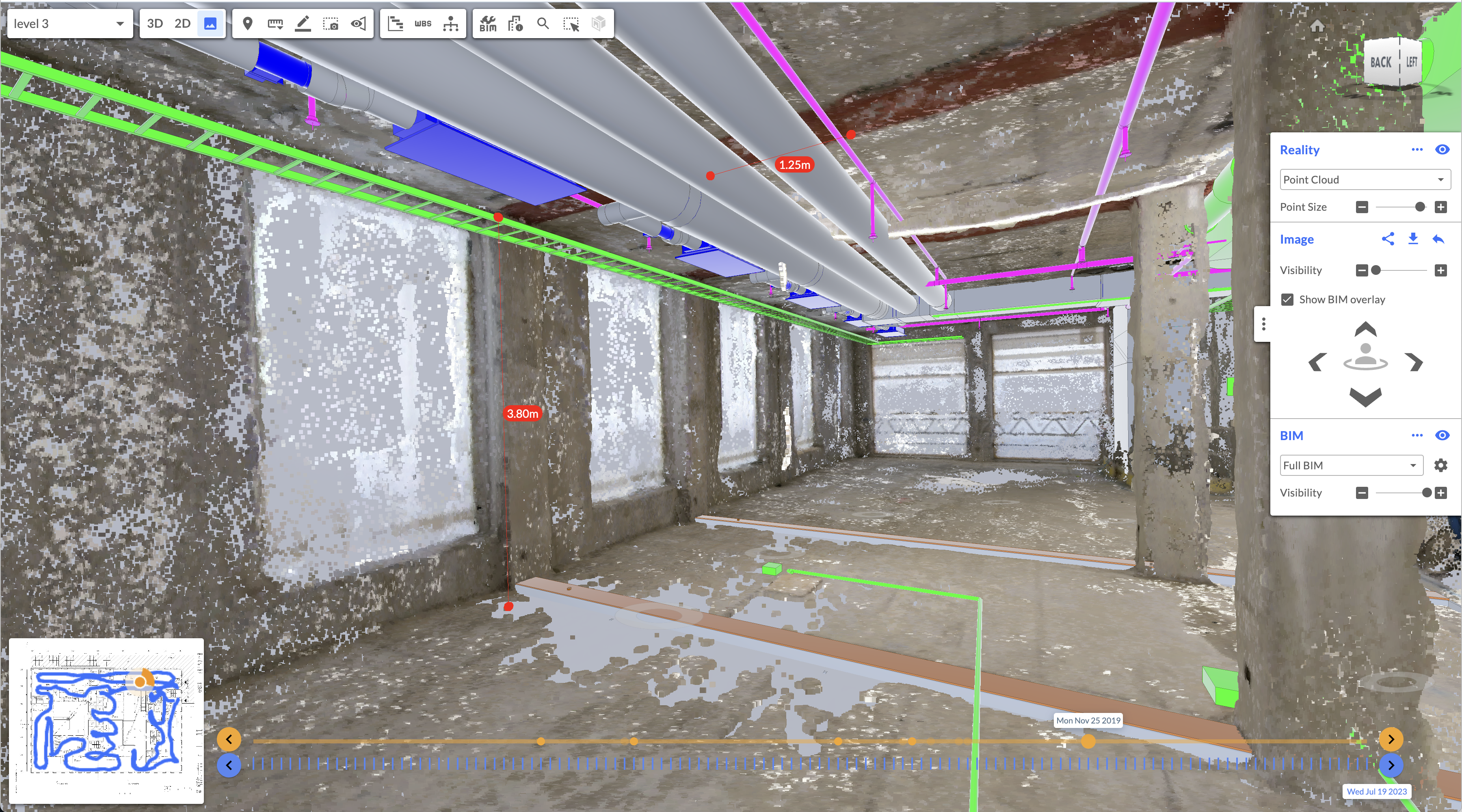

Plus, there's the added benefit of a rewind button. Because Reconstruct creates a true time machine for construction, stakeholders can not only assess a project's current conditions but also turn back the clock to review progress and installations at any other date or time.

Reasons to supplement 360 progress capture

There are many benefits to capturing the reality of a job site with a 360 camera. Construction progress monitoring with a 360 camera provides valuable insights into the ongoing developments. The devices are inexpensive, virtually any employee can perform the capture, and capture can be performed very quickly. These factors add up so that it's easy for organizations to create a digital twin that can be shared amongst all stakeholders. Still, there are situations in which additional forms of reality capture may prove helpful.

For example, smartphones do an exceptional job of capturing high-resolution still images of complex installations, such as pipes or wiring. A simple photo of a wall will do the trick—photogrammetry engines such as Reconstruct will automatically place that photo in space and over time, then blend the footage with the rest of the digital twin to produce a single source of project truth.

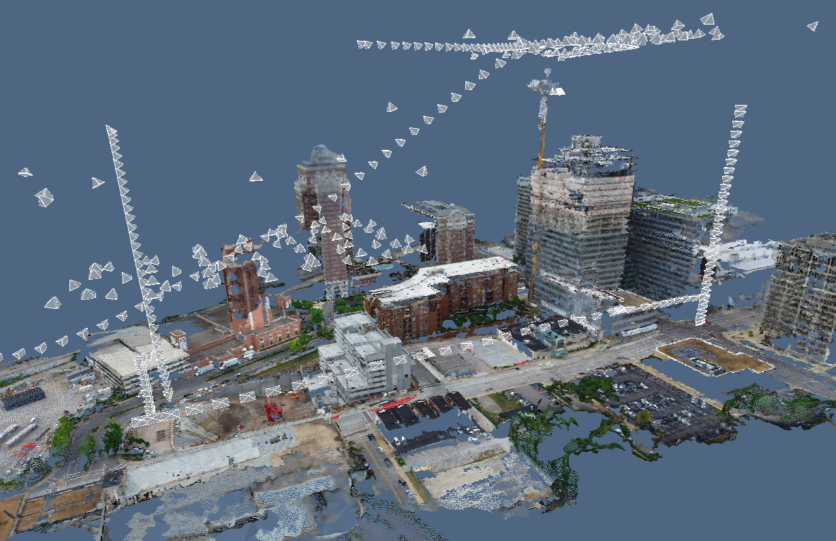

Drones are perfect for exterior capture—they can help capture footage of hard-to-reach areas that may also be unsafe to access.

Laser scanning is often the top choice for final as-built documentation of a project. It's highly accurate, but it's costly and time-consuming, which is why it's often reserved for assisting in the creation of final measurements.

About Reconstruct

Reconstruct has set the standard for digital twins for construction—and for 360 progress capture. There’s no easier way to bring all your reality data (including 360 capture) together to create one single source of project truth. To see your project in Reconstruct, request a personalized demo today.

.gif)

.png)