When using Reconstruct to perform construction progress monitoring of a job site, stakeholders can also utilize Reconstruct’s robust annotation tools to identify and markup any visualized concerns on the digital twin itself. This article will zero in on how stakeholders across the construction, inspection, and engineering industries use these collaborative annotation tools to rapidly share information about visualized issues before they snowball into costly, delay-causing rework.

Annotating a digital twin for construction

Reconstruct allows on-site team members to rapidly capture reality data from the job site in minutes. All footage can be blended together in space and over time to create a 3D scan (also known as a site survey or current conditions assessment) of the job site. This can be done by virtually any team member using devices such as a smartphone, 360 camera, drone, or laser scanner.

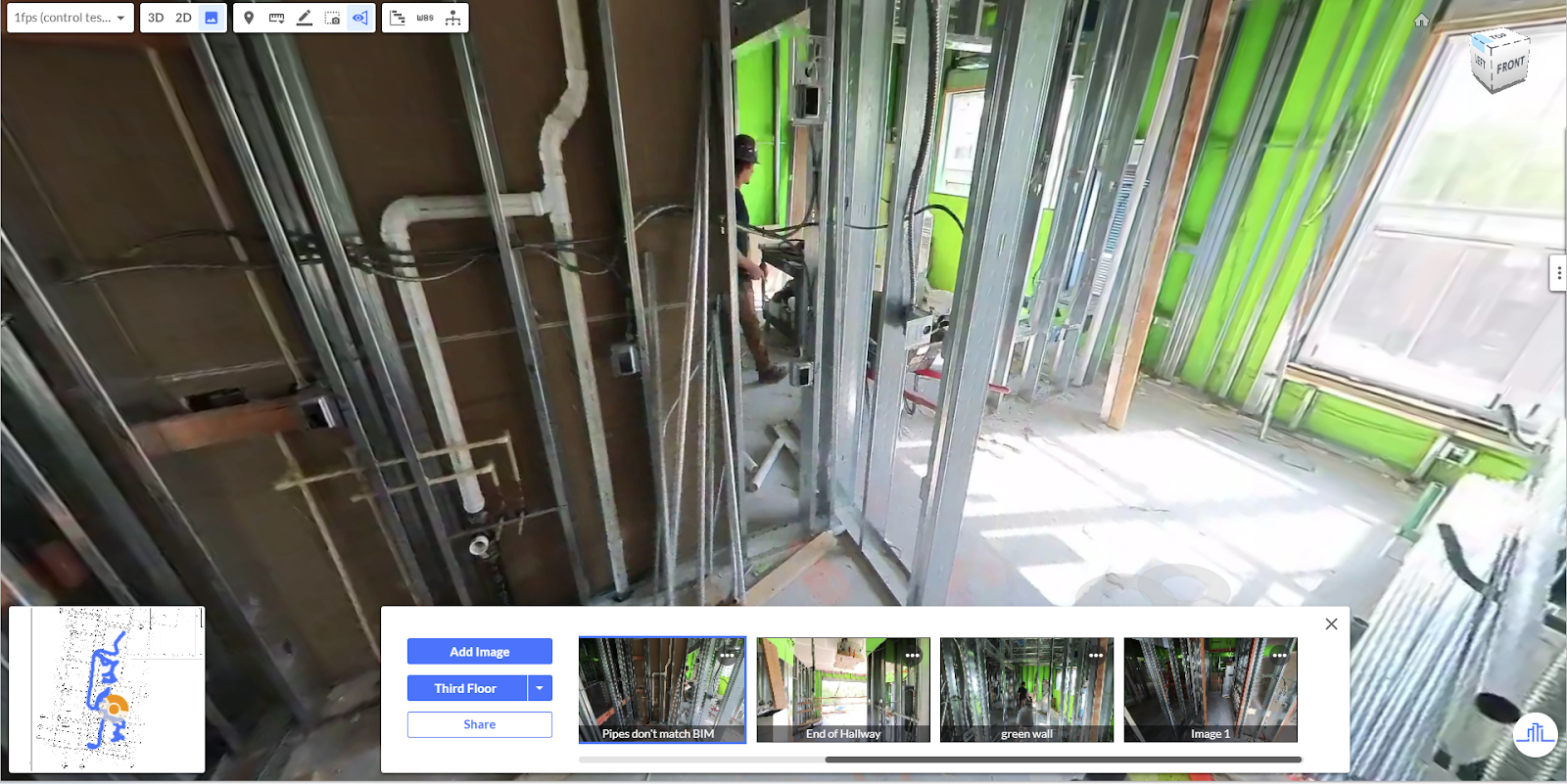

Once the photogrammetry engine has converted the reality capture data into an immersive, measurable walkthrough of the job site, users can leverage a variety of annotation tools to swiftly identify and communicate issues and concerns on the job site, even from half a world away. Additional features, such as overlaying 2D and 3D design drawings and BIM over reality data, make it that much easier to pinpoint mistakes by revealing what’s there versus what should be there.

Once concerns have been identified and the digital twin is properly annotated, users have two options:

- Allow other stakeholders to review annotations via virtual walkthrough or via exported CSV report.

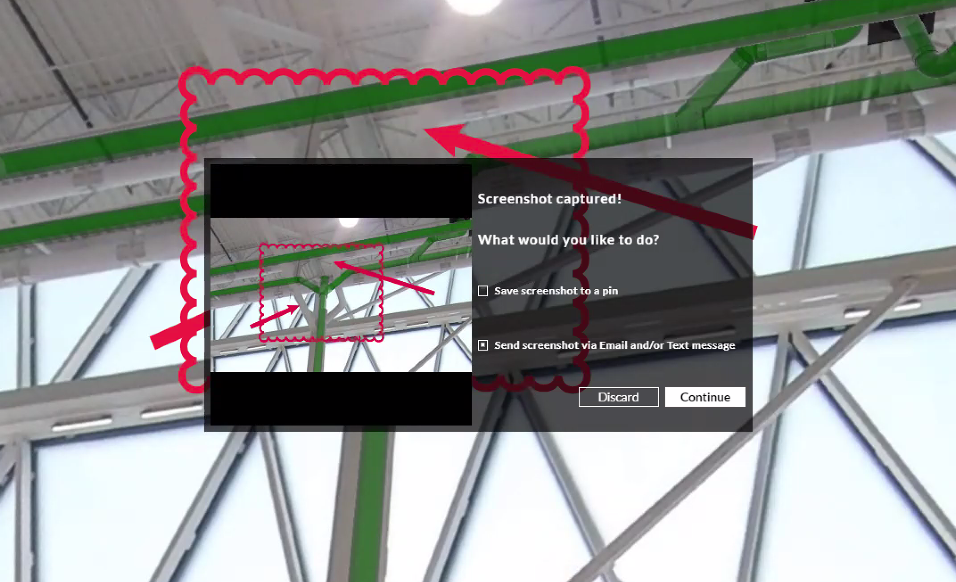

- Export a screenshot of the concern, then e-mail or SMS key persons the necessary images and instructions. For example, if a remote inspector discovers plumbing has been installed 6 inches off, they can screenshot a photo of the mistake with a message to correct the error before pouring concrete.

Benefits of annotation using construction progress monitoring software

In both instances, both on-site and remote stakeholders are able to collaborate, performing construction quality control without the expense or logistical challenges of constant travel. What's more, inspectors have the opportunity to review all work before next steps, even if they cannot physically walk the job site. In other words, annotation tools and the quick collaboration options that accompany them enable stakeholders to work together to ensure jobs are completed as planned, on time, and on budget.

Broadly, the benefits of communicating and collaborating directly on the digital twin include:

- Automatic record keeping within the digital twin itself for effective construction remote monitoring

- The ability to immediately export urgent requests to on-site field teams

- The ability for multiple stakeholders across the world to collaborate on and communicate about a single source of project truth

- The ability to compare plans against reality at every step along the construction timeline, making it that much easier for stakeholders to identify small problems before they turn into costly mistakes

- A reduction in costly overwork that stems from faster, more frequent construction quality control

About Reconstruct

Reconstruct has set the gold standard for digital twins in the construction industry, allowing virtually anyone on site to use even the simplest of reality capture devices to create an immersive, accurate 3D site survey (and 2D floorplans) of a construction project. Then, once the current conditions assessment is ready, stakeholders all over the world can utilize annotation tools to identify problems and concerns and dispatch actionable requests to the right teams immediately.

To learn more about Reconstruct, schedule a personalized demo today.