These days, most organizations across the construction, engineering, and inspection industries are looking for ways to streamline work without sacrificing quality. As a result, more and more stakeholders are turning to certain types of technology to bring the job site directly to them without unnecessarily tying up resources. A digital twin for construction is one of the most popular types of this time and money-saving technology.

In this article, we will discuss four key reasons to consider a digital twin for construction if your organization wants to reduce the resources dedicated to job-site walkthroughs, laser scanning, and other resource-intensive activities.

1. New technology enables virtually any employee to create a digital twin

While laser scanning remains an incredibly accurate way to capture and measure a job site, it is also time-consuming and expensive and needs to be performed by an expert. This means that laser scanning is, in most cases, not a suitable way to perform reality capture for frequent construction progress monitoring. Instead, laser scanning is typically reserved for preconstruction assessments of current conditions or to capture the final state of construction during as-built documentation.

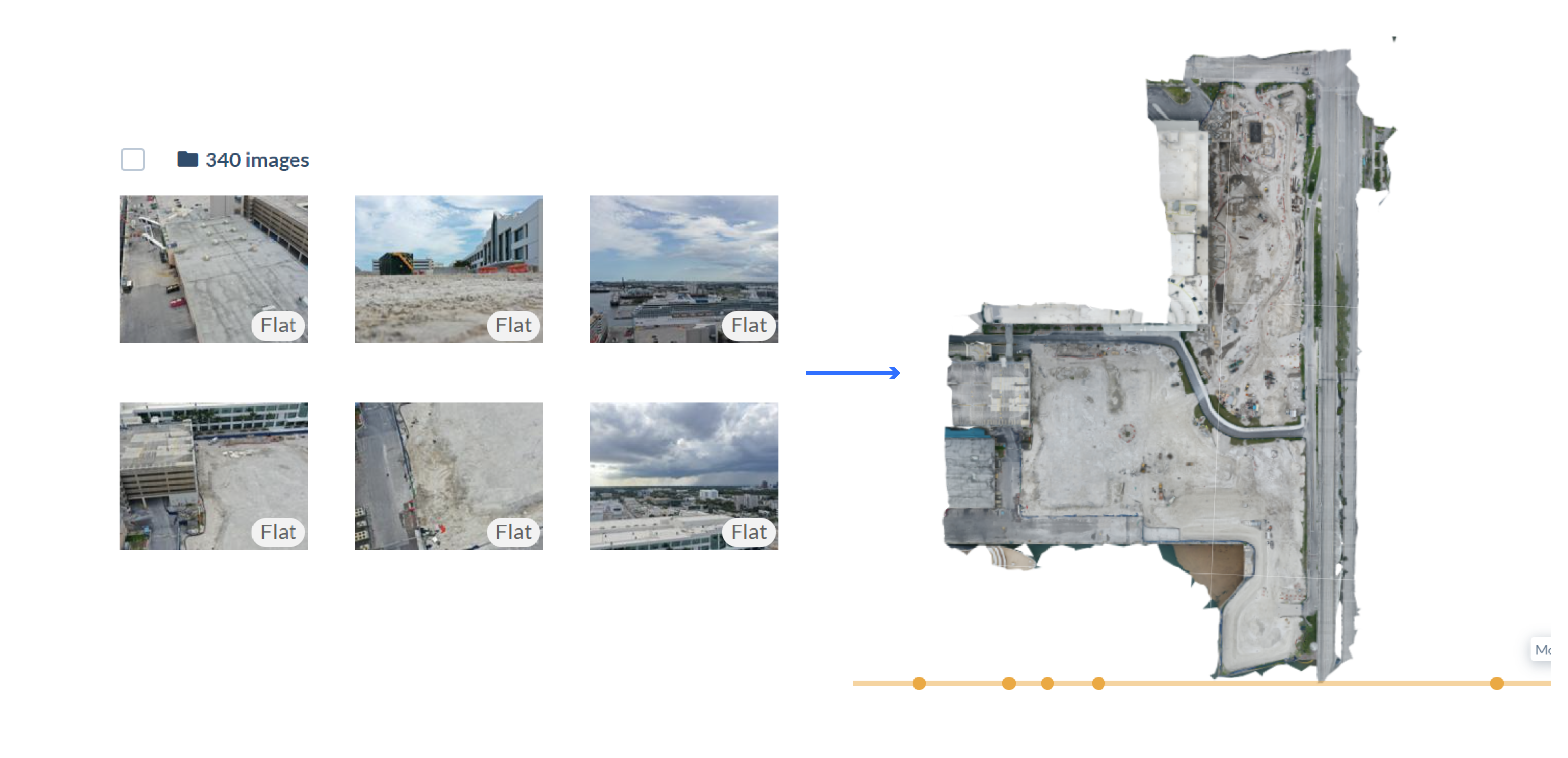

Fortunately, significant strides in photogrammetry and reality mapping technology have enabled organizations to perform rapid and incredibly accurate reality capture of job sites using hardware as simple as a smartphone, 360 camera, or reasonably priced drone. Best of all, these devices can be operated by virtually any employee without disrupting construction. 360 capture, for example, records panoramic images of the job site as fast as 1,000 square feet per minute.

Additionally, any footage captured via 360 camera, smartphone, drone, or laser scanner can be blended into one single source of project truth regardless of when it was captured and on what device. This means that all teams and stakeholders on the job (even from different organizations) can combine their footage to produce one blended, digital twin of construction progress in space and over time.

Related: What is a digital twin for construction?

2. That digital twin is highly measurable and totally immersive

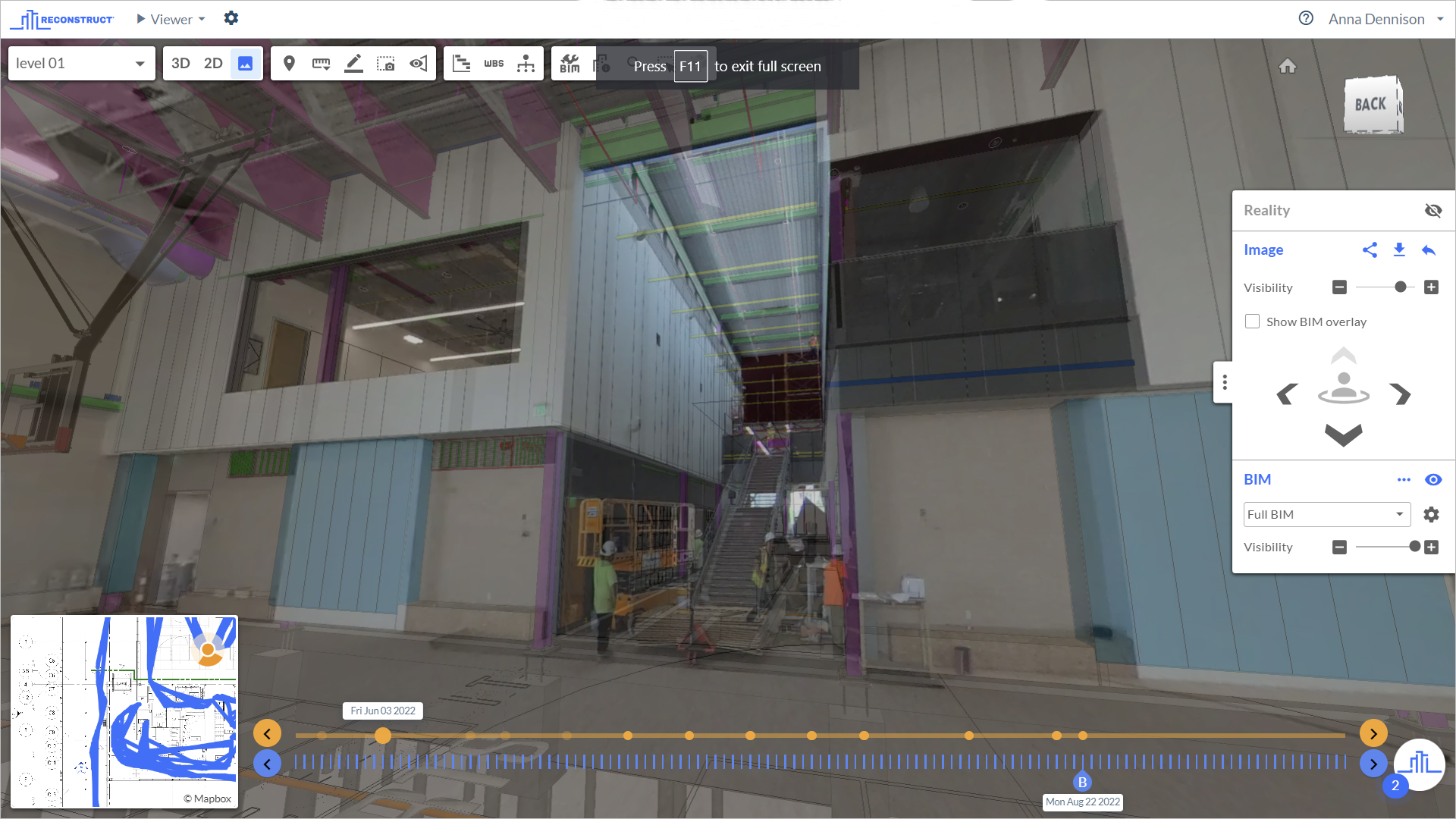

The blended footage produced by a photogrammetry engine offers various benefits to stakeholders. Chiefly, this digital twin can replace many on-site inspections during the construction phase. For example, when Reconstruct’s photogrammetry engine is used, the digital twin is highly measurable and provides an immersive walkthrough of the job site as realistic and detail-rich as stepping foot in the construction zone itself.

Additionally, users can deploy various features and tools to communicate visualized issues, overlay designs and drawings atop the digital twin, review automatically generated 2D floor plans, use cut-and-fill measuring tools to determine how much dirt has been moved, and more.

3. Curated tours of the job site can be shared

When using a reality mapping engine like Reconstruct, there is no limit to how many users you can invite to view the digital twin. That means there is no reason to leave stakeholders or collaborators in the dark about construction.

That said, sometimes it is either unnecessary or unfavorable to invite certain vendors and trades to view the entire digital twin. Or, there is simply more information available within the software than what needs to be shared with certain collaborators. Instead, users can share a quick and focused snapshot of a given aspect of construction.

For this use case, Reconstruct offers a tool called Project Snapshot. It allows Reconstruct users to curate a focused tour of construction rapidly, perfect for quick communication about an aspect of construction or to offer an added glance at a recent installation at an OAC meeting.

4. Archives serve as a time machine for construction

Even after construction on a given project is complete, the benefits of having a digital twin continue. For example, a digital twin can serve as a Time Machine for Construction™ should questions arise from tenants, maintenance, or future owners. A digital twin for construction can also be helpful should there be a question of construction liability down the road.

Regardless of why the digital twin is needed, the ability to turn back time to prove how construction was performed without the cost and delay of demolition is of serious benefit to virtually every type of stakeholder, from owner to owner’s representative to contractor to trade.

About Reconstruct

Reconstruct has set the gold standard for digital twins in construction, inspection, and engineering. To learn more about how easy it is to create a digital twin of your job site, set up a personalized demo today.